Efficiently manage thermal challenges in high-performance electronics with our specialized Thermal Via PCB solutions.

Product Overview

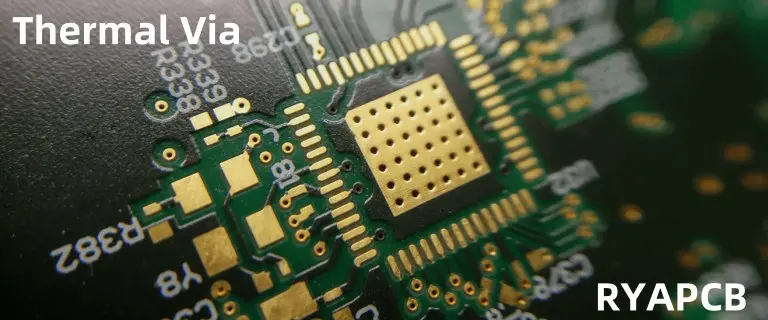

Thermal Via PCBs represent cutting-edge heat management technology designed to address the critical thermal challenges in modern electronic systems. These specialized printed circuit boards feature strategically placed thermal vias – small, plated holes filled with thermally conductive materials that create efficient heat transfer pathways from hot components to heat sinks or ground planes.

Key Features

Superior Heat Dissipation: Our thermal vias are precisely engineered to maximize heat transfer efficiency, reducing component temperatures by up to 30% compared to standard PCBs. The optimized via placement and sizing ensure optimal thermal performance across the entire board.

High Thermal Conductivity: Featuring copper-filled vias with thermal conductivity ratings of 400+ W/mK, these PCBs provide exceptional heat transfer capabilities. The thermal interface is further enhanced through advanced plating techniques that eliminate air gaps and thermal barriers.

Flexible Design Options: Available in various configurations including micro-vias (50-150μm), standard vias (200-500μm), and large thermal vias (up to 1mm diameter). Custom via patterns can be tailored to specific component layouts and thermal requirements.

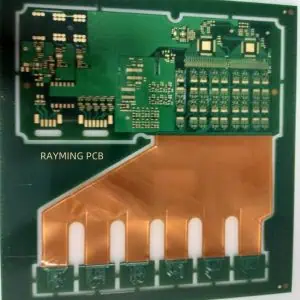

Multi-Layer Integration: Seamlessly integrates with 4-16 layer PCB designs, allowing for complex routing while maintaining optimal thermal performance. Thermal vias can be strategically placed to connect multiple ground planes and thermal layers.

Technical Specifications

- Via Fill Materials: Copper, silver-filled epoxy, or thermally conductive paste

- Thermal Resistance: As low as 0.1°C/W per via

- Operating Temperature Range: -55°C to +150°C

- Board Thickness: 0.4mm to 6.0mm

- Via Aspect Ratios: Up to 12:1 for optimal manufacturability

Applications

Power Electronics: Ideal for DC-DC converters, power modules, and voltage regulators where efficient heat removal is critical for reliability and performance.

LED Lighting Systems: Essential for high-power LED arrays requiring effective thermal management to maintain light output and extend operational life.

Automotive Electronics: Perfect for engine control units, power steering modules, and electric vehicle charging systems operating in demanding thermal environments.

Telecommunications: Crucial for 5G base stations, optical transceivers, and high-frequency amplifiers where component density and heat generation are significant concerns.

Industrial Controls: Suitable for motor drives, welding equipment, and process control systems requiring robust thermal performance in harsh environments.

Competitive Advantages

Our Thermal Via PCB technology delivers measurable performance improvements including reduced component failure rates, extended product lifespan, and enhanced system reliability. The precision manufacturing process ensures consistent thermal performance across production runs, while our design optimization services help customers achieve maximum thermal efficiency within their specific constraints.

Quality Assurance: Every thermal via PCB undergoes rigorous thermal cycling tests and thermal impedance measurements to guarantee performance specifications. ISO 9001 and IPC-A-600 certified manufacturing ensures consistent quality and reliability.

Transform your thermal management challenges into competitive advantages with our proven Thermal Via PCB solutions – engineered for performance, built for reliability.