Overview

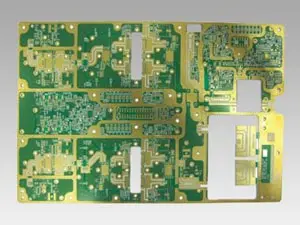

Rogers Corporation, a global leader in engineered materials with over 190 years of innovation, offers cutting-edge flexible circuit solutions designed to power, protect, and connect the modern world. Rogers flexible PCBs provide high-frequency performance and flexibility, making them ideal for applications where space is limited and high-frequency performance and reliability are critical.

Key Features & Benefits

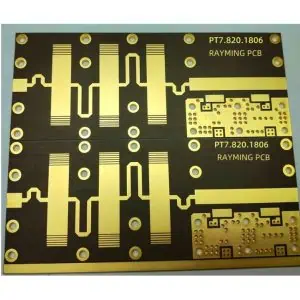

Superior Electrical Performance

- High-Frequency Excellence: Rogers laminates offer superior dielectric constant and temperature stability when compared with standard FR4 materials

- Low Loss Technology: Engineered for minimal signal loss at microwave and RF frequencies

- Controlled Impedance: Rogers materials offer uniform controlled impedance with minimum tolerance in contrast to standard FR-4 materials

Advanced Material Properties

- Temperature Stability: Excellent performance across extreme temperature ranges

- Moisture Resistance: Minimal water absorption characteristic makes it appropriate for use in high-humidity applications

- Chemical Resistance: Superior resistance to harsh environmental conditions

- Dimensional Stability: Maintains form factor integrity under stress

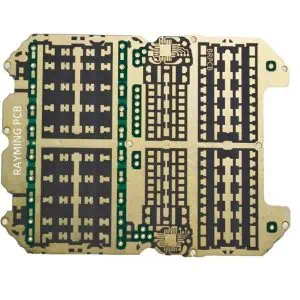

Mechanical Flexibility

- Dynamic Bend Capability: Flexible PCBs are thin, lightweight, and can be bent or folded to fit into tight spaces

- Durability: More durable and resistant to vibration and shock, which makes them ideal for use in harsh environments

- Compact Design: Enables lighter, more compact electronic assemblies

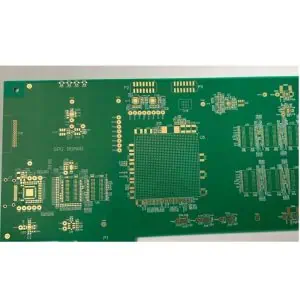

Technical Specifications

Material Composition

- Base Materials: Composite of ceramic and polymer materials that provide excellent dielectric properties, low loss, and high thermal conductivity

- Conductor: Thin layer of copper foil for electrical connectivity

- Substrate Options: Various Rogers material series including RO4000®, RO3000®, and specialized flexible formulations

Performance Characteristics

- Frequency Range: Optimized for microwave and millimeter wave applications

- Dielectric Constant: Precisely controlled for consistent signal integrity

- Loss Tangent: Ultra-low loss for high-frequency applications

- Thermal Conductivity: Enhanced heat dissipation capabilities

Applications

Aerospace & Defense

Rogers flexible PCBs are commonly used in aerospace, military applications, where high-frequency performance and reliability are critical. These applications benefit from:

- Radar systems and antenna arrays

- Avionics equipment requiring temperature stability

- Communication systems in harsh environments

Medical Electronics

- Implantable devices requiring biocompatibility

- Portable medical equipment

- High-precision diagnostic instruments

Consumer Electronics

- Mobile devices and smartphones

- Wearable technology

- Compact electronic assemblies

Automotive

- Advanced driver assistance systems (ADAS)

- Vehicle radar and communication systems

- Electric vehicle power management

Industrial Applications

- High-power RF systems

- Telecommunications infrastructure

- IoT and connected devices

Manufacturing Excellence

Processing Advantages

Rogers materials can be processed similarly to FR-4, enabling efficient manufacturing while delivering superior performance. The materials are compatible with standard PCB fabrication processes including:

- Chemical surface preparation

- Plating and metallization

- Lamination and bonding

- Precision drilling and routing

Quality Assurance

Rogers Corporation maintains strict quality standards with:

- ISO-certified manufacturing facilities

- Comprehensive testing protocols

- Global supply chain reliability

- Technical support and design collaboration

Competitive Advantages

- Industry Leadership: Rogers RO4000 hydrocarbon ceramic laminates and prepregs are the industry leader

- Proven Reliability: Decades of proven performance in mission-critical applications

- Design Flexibility: Customizable solutions for specific application requirements

- Global Support: Worldwide technical support and manufacturing capabilities

- Innovation: Continuous R&D investment in next-generation materials

Conclusion

Rogers flexible circuit solutions represent the pinnacle of high-performance flexible electronics technology. Whether for aerospace, medical, automotive, or consumer applications, these advanced materials deliver unmatched reliability, performance, and design flexibility. Rogers flexible circuit boards play a critical role in the design and production of electronic devices, enabling engineers to create innovative solutions that meet the demanding requirements of today’s advanced electronic systems.