Accelerate Your Product Development with Industry-Leading Rigid-Flex Solutions

When time-to-market is critical and your design demands the unique advantages of rigid-flex technology, our Quick Turn Rigid Flex Combined Board Rush Services deliver the speed, quality, and reliability you need to stay ahead of the competition.

What is Rigid-Flex Technology?

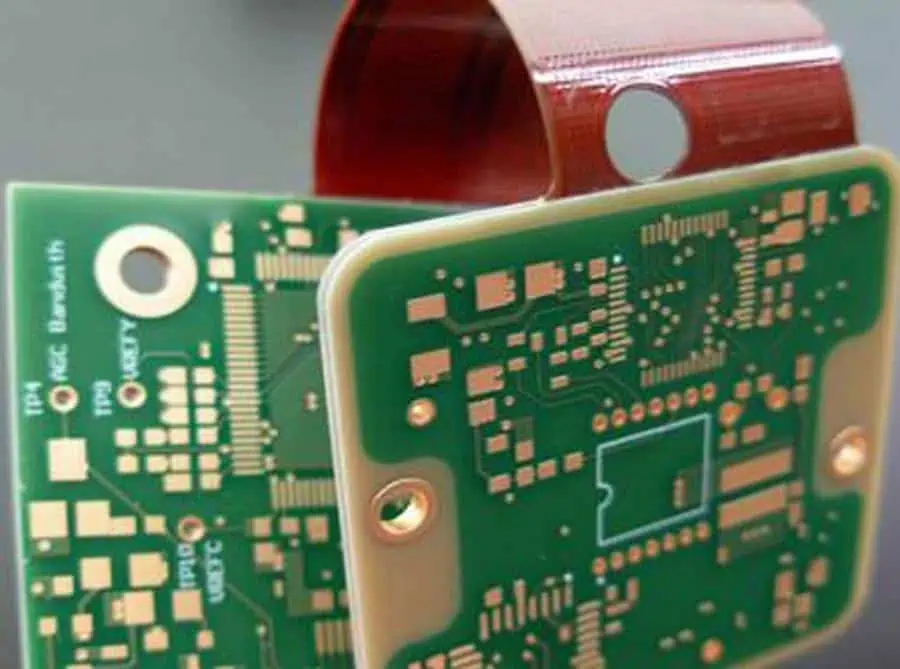

Rigid-flex PCBs combine the best of both worlds by integrating rigid circuit boards with flexible interconnects in a single assembly. This innovative approach eliminates the need for connectors, cables, and discrete wiring harnesses while providing exceptional mechanical reliability and space optimization.

Key Benefits

Ultra-Fast Turnaround Times

- Express 5-7 day delivery for standard configurations

- Rush 3-5 day options for urgent projects

- Same-day quoting and engineering review

Superior Design Flexibility

- Seamless integration of rigid and flexible sections

- Complex 3D geometries and space-constrained applications

- Reduced assembly time and elimination of interconnect failures

Enhanced Reliability

- Fewer connection points mean fewer failure modes

- Improved signal integrity and reduced EMI

- Extended product lifespan in high-vibration environments

Cost-Effective Solutions

- Reduced overall system costs through elimination of connectors

- Lower assembly labor requirements

- Simplified supply chain management

Technical Specifications

- Layer Count: 2-20 layers (rigid sections), 1-4 layers (flex sections)

- Board Thickness: 0.1mm – 3.2mm (rigid), 0.05mm – 0.5mm (flex)

- Minimum Via Size: 0.1mm (4 mil)

- Minimum Trace/Space: 0.075mm/0.075mm (3/3 mil)

- Bend Radius: Dynamic: 10x thickness, Static: 5x thickness

- Materials: Polyimide flex cores, FR-4 rigid sections, various coverlay options

Applications

Our Quick Turn Rigid Flex services are ideal for:

- Medical Devices: Implantables, diagnostic equipment, wearable monitors

- Aerospace & Defense: Avionics, satellite systems, military communications

- Consumer Electronics: Smartphones, tablets, wearable technology

- Automotive: Dashboard electronics, sensor systems, infotainment

- Industrial: Robotics, automation equipment, test instrumentation

Manufacturing Capabilities

Advanced Processing

- Controlled impedance matching

- Via-in-pad technology

- Blind and buried vias

- Sequential lamination processes

Quality Assurance

- IPC Class 2 and Class 3 compliance

- 100% electrical testing

- Automated optical inspection (AOI)

- Cross-sectional analysis and microsectioning

Rush Service Options

Standard Rush (5-7 days)

- Complete fabrication and assembly

- Standard material options

- Full electrical testing included

Express Rush (3-5 days)

- Priority production scheduling

- Expedited material procurement

- Dedicated engineering support

Emergency Rush (24-72 hours)

- Available for select configurations

- Premium service with dedicated resources

- Direct communication with production team

Why Choose Our Services?

With over 20 years of experience in advanced PCB manufacturing, we understand the unique challenges of rigid-flex technology. Our state-of-the-art facility, experienced engineering team, and commitment to quality ensure your critical projects are delivered on time and to specification.

Get Started Today Upload your design files for an instant quote, or contact our technical team to discuss your specific requirements. We’re ready to turn your complex designs into reality with the speed and precision your project demands.