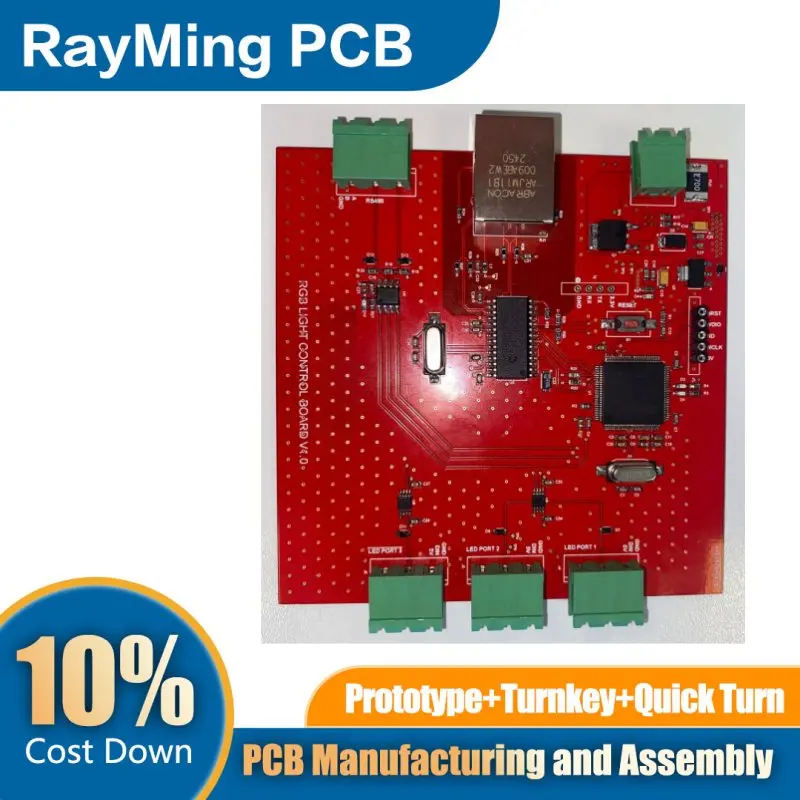

Premium PCB Fabrication and Electronic Assembly Solutions

Transform your electronic designs into reality with our comprehensive printed circuit board manufacturing and assembly services. We specialize in delivering high-quality PCBs and complete electronic assemblies for industries ranging from consumer electronics to aerospace applications.

PCB Manufacturing Capabilities

Advanced PCB Fabrication Services:

- Single-sided, double-sided, and multi-layer PCBs (up to 32 layers)

- High-density interconnect (HDI) boards with microvias

- Flexible and rigid-flex PCB solutions

- High-frequency RF/microwave boards

- Metal core PCBs for LED and power applications

- Thick copper PCBs for high-current applications

Technical Specifications:

- Minimum trace width: 3 mil (0.075mm)

- Minimum via size: 4 mil (0.1mm)

- Layer count: 1-32 layers

- Board thickness: 0.2mm – 6.0mm

- Copper weight: 0.5oz – 6oz

- Surface finishes: HASL, OSP, ENIG, Immersion Silver, Hard Gold

Electronic Assembly Services

Complete PCB Assembly Solutions:

- Surface Mount Technology (SMT) assembly

- Through-hole component insertion

- Mixed technology assemblies

- Ball Grid Array (BGA) and micro-BGA placement

- Fine-pitch component assembly (0201 components)

- Cable and wire harness assembly

- Box build and system integration

Quality Assurance & Testing:

- Automated Optical Inspection (AOI)

- In-Circuit Testing (ICT)

- Functional testing and programming

- X-ray inspection for hidden joints

- Flying probe testing

- Environmental stress screening

Industries We Serve

Our PCB and assembly services support diverse applications across multiple sectors:

- Automotive electronics and EV systems

- Medical devices and diagnostic equipment

- Industrial automation and control systems

- Telecommunications and networking equipment

- Aerospace and defense electronics

- Consumer electronics and IoT devices

- LED lighting and power electronics

Manufacturing Standards & Certifications

- ISO 9001:2015 Quality Management

- IPC-A-610 Class 2 and Class 3 assembly standards

- IPC-6012 PCB fabrication standards

- RoHS and REACH compliance

- UL certification available

- Military and aerospace specifications (MIL-SPEC)

Competitive Advantages

Fast Turnaround Times:

- Prototype PCBs: 24-48 hours

- Standard production: 5-10 working days

- Assembly services: 3-7 working days

- Express services available

Cost-Effective Solutions:

- Competitive pricing for all volume levels

- No setup fees for standard specifications

- Volume discounts for production quantities

- DFM (Design for Manufacturing) optimization

Global Supply Chain:

- Sourcing of electronic components

- Component procurement and kitting

- Obsolescence management

- Counterfeit component prevention

Design Support Services

- PCB layout design and optimization

- Design for Manufacturing (DFM) analysis

- Design for Test (DFT) consultation

- Signal integrity analysis

- Thermal management solutions

- EMC/EMI design considerations

Quality Control Process

Every PCB and assembly undergoes rigorous quality control:

- Incoming material inspection

- In-process quality monitoring

- Final inspection and testing

- Statistical process control

- Traceability documentation

- Customer-specific testing requirements

Ordering Process

Simple 4-Step Process:

- Quote Request – Upload Gerber files and BOM

- Engineering Review – DFM analysis and optimization

- Production – Automated manufacturing and assembly

- Quality Assurance – Testing and final inspection

Technical Support

Our experienced engineering team provides comprehensive support throughout your project lifecycle, from initial design consultation to post-production support and field service.

Contact Information:

- Technical hotline for design support

- Online quote system for instant pricing

- Dedicated account managers for volume customers

- 24/7 customer portal for order tracking