Advanced PCB Solutions for Complex Electronic Applications

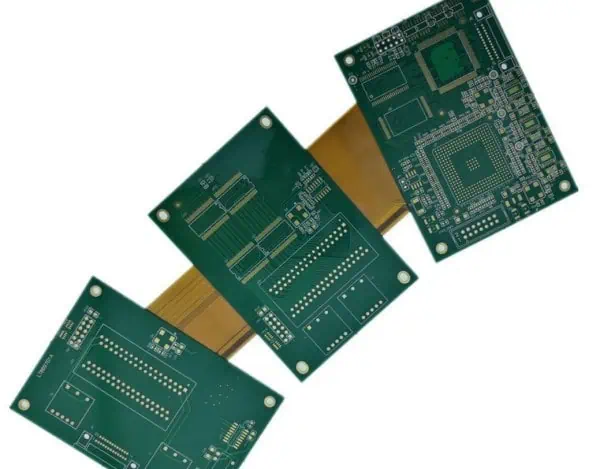

Our Multilayer Rigid Flex boards represent the pinnacle of PCB technology, seamlessly combining the structural integrity of rigid boards with the flexibility of flex circuits in a single, integrated solution. These sophisticated circuit boards feature multiple layers of conductors separated by dielectric materials, with designated flexible sections that allow for three-dimensional routing and dynamic movement.

Key Features

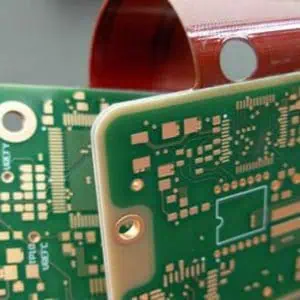

Hybrid Construction: Engineered with both rigid and flexible sections, enabling complex folding patterns and space-efficient designs that would be impossible with traditional rigid boards alone.

Multi-Layer Architecture: Available in configurations ranging from 4 to 20+ layers, providing extensive routing capabilities for high-density component placement and complex signal management.

Superior Signal Integrity: Controlled impedance characteristics and reduced electromagnetic interference through optimized layer stackup design and advanced materials.

Enhanced Reliability: Eliminates the need for connectors and cables between rigid sections, reducing potential failure points and improving overall system reliability by up to 85%.

Space Optimization: Enables compact, three-dimensional packaging solutions that can reduce overall product size by 30-50% compared to traditional rigid board assemblies.

Applications

Ideal for aerospace and defense systems, medical devices, automotive electronics, telecommunications equipment, and consumer electronics where space constraints, reliability requirements, and complex routing demands converge. Particularly valuable in applications requiring movement between rigid sections, such as laptop hinges, camera modules, and wearable devices.

Technical Specifications

- Layer Count: 4-20+ layers

- Flex Section Thickness: 0.1mm to 0.5mm

- Rigid Section Thickness: 0.4mm to 6.0mm

- Minimum Bend Radius: 5x total thickness

- Operating Temperature: -55°C to +125°C

- Dielectric Materials: Polyimide, FR-4, Rogers, and specialty materials

Our manufacturing process employs advanced lamination techniques and precision drilling to ensure consistent quality and reliability across all layers and transitions between rigid and flexible sections.