Precision-Engineered PCBs for Critical Medical Applications

Our FDA compliant medical device PCBs are manufactured to the highest standards of quality, reliability, and regulatory compliance, ensuring your medical devices meet stringent healthcare industry requirements.

Key Features

Regulatory Compliance

- Full FDA compliance with 21 CFR Part 820 Quality System Regulation

- ISO 13485 certified manufacturing processes

- IPC Class III medical-grade standards adherence

- Complete traceability and documentation for regulatory submissions

Superior Quality Standards

- Biocompatible materials suitable for patient contact applications

- RoHS compliant lead-free manufacturing

- Controlled impedance matching for signal integrity

- Ultra-low EMI/EMC emissions for sensitive medical environments

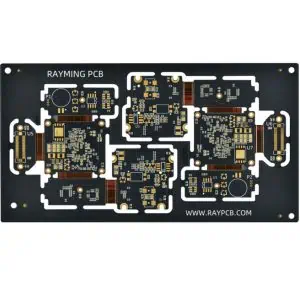

Advanced Manufacturing Capabilities

- High-density interconnect (HDI) technology for compact designs

- Multilayer constructions up to 32 layers

- Microvias and blind/buried via technology

- Fine pitch component compatibility down to 0.4mm BGA

Specialized Materials

- Medical-grade FR-4 and polyimide substrates

- Halogen-free options for enhanced safety

- High-temperature resistant materials for sterilization processes

- Low outgassing materials for implantable devices

Applications

Our medical PCBs power critical healthcare technologies including patient monitoring systems, diagnostic equipment, surgical instruments, implantable devices, imaging systems, and therapeutic equipment. Each board undergoes rigorous testing protocols including electrical testing, thermal cycling, and biocompatibility verification.

Quality Assurance

Every PCB is manufactured in our ISO 13485 certified cleanroom facility with complete lot traceability, automated optical inspection (AOI), in-circuit testing (ICT), and comprehensive documentation packages ready for FDA submissions. Our experienced engineering team provides design for manufacturing (DFM) support to optimize your medical device PCB for reliability, cost-effectiveness, and regulatory approval.

Trust your critical medical applications to PCBs engineered for life-saving performance.