Our Immersion Tin PCB finish delivers exceptional solderability and reliability for modern electronic applications requiring lead-free manufacturing processes. This advanced surface treatment provides a flat, uniform coating that ensures consistent electrical performance while meeting stringent environmental compliance standards.

Key Features:

- Lead-Free Compliance: Fully RoHS compliant finish eliminates lead content for environmentally responsible manufacturing

- Excellent Solderability: Superior wetting characteristics enable reliable solder joint formation with both lead-free and traditional solders

- Flat Surface Profile: Creates an ultra-smooth finish ideal for fine-pitch components and high-density layouts

- Cost-Effective Solution: More economical than ENIG while maintaining excellent performance characteristics

- Wide Component Compatibility: Suitable for SMT assembly, through-hole components, and mixed technology boards

Technical Specifications:

- Tin thickness: 0.8-1.2 micrometers

- Surface roughness: Ra < 0.5 μm

- Shelf life: 12+ months with proper storage

- Operating temperature range: -55°C to +125°C

- Excellent corrosion resistance in standard environments

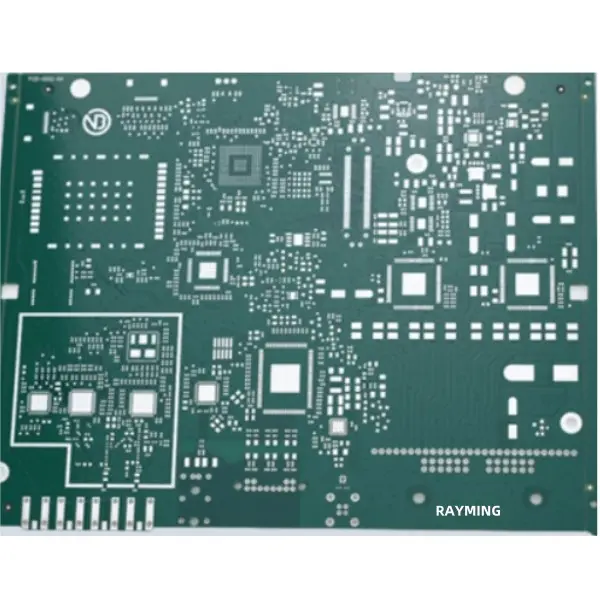

Applications: Perfect for consumer electronics, telecommunications equipment, automotive systems, and industrial controls where lead-free processing is required. Particularly well-suited for prototyping and medium-volume production runs where cost optimization is important without compromising quality.

Quality Assurance: Each batch undergoes rigorous testing including solderability analysis, thickness measurement, and adhesion testing to ensure consistent performance. All boards are manufactured in ISO 9001:2015 certified facilities with full traceability documentation.

Choose Immersion Tin finish for your next project when you need reliable, cost-effective lead-free PCB finishing that doesn’t compromise on quality or performance.