Engineered for Power. Built for Performance.

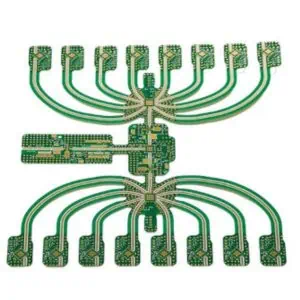

Our heavy copper PCB fabrication service delivers robust, high-performance printed circuit boards designed specifically for demanding high-current applications. Featuring copper thickness from 3oz to 20oz (105μm to 700μm), these specialized PCBs provide superior current-carrying capacity, enhanced thermal management, and exceptional reliability for power electronics.

Key Features

Superior Current Handling Heavy copper traces support significantly higher current loads compared to standard PCBs, making them ideal for power converters, motor drives, welding equipment, and automotive applications. The increased copper thickness reduces resistance and minimizes voltage drops across the circuit.

Enhanced Thermal Performance The substantial copper mass acts as an integrated heat sink, efficiently dissipating heat generated by high-power components. This thermal management capability extends component lifespan and maintains stable operation under demanding conditions.

Exceptional Mechanical Strength Heavy copper construction provides increased mechanical durability and vibration resistance, essential for industrial equipment, aerospace applications, and harsh operating environments.

Precise Manufacturing Control Our advanced fabrication process ensures consistent copper thickness distribution, precise trace geometry, and reliable via fill for optimal electrical performance. We maintain tight tolerances for impedance control and layer registration.

Applications

Power supplies and converters, motor control systems, automotive electronics, solar inverters, welding equipment, UPS systems, LED lighting drivers, industrial automation equipment, and high-frequency switching circuits.

Technical Specifications

- Copper thickness: 3oz to 20oz (105μm to 700μm)

- Layer count: 2 to 16 layers

- Minimum trace width/spacing: Varies by copper weight

- Via sizes: Micro vias to large diameter vias

- Surface finishes: HASL, ENIG, OSP, Immersion Silver

- Operating temperature: -55°C to +125°C

Ready to power your next project? Contact our engineering team to discuss your heavy copper PCB requirements and receive a custom fabrication quote tailored to your high-current application needs.