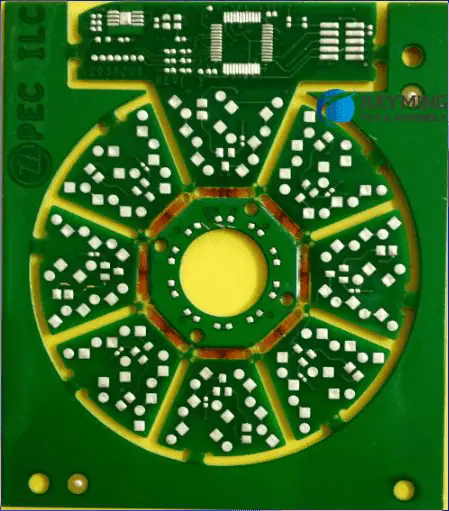

Heat Spreader PCB – Thermal Distribution Technology

Advanced thermal management solution engineered to efficiently distribute and dissipate heat across printed circuit boards. This specialized PCB technology incorporates enhanced copper layers and optimized trace routing to create uniform thermal distribution, preventing hot spots and maintaining optimal operating temperatures for sensitive electronic components.

Key Features:

- Enhanced Thermal Conductivity: Utilizes thick copper planes and thermally conductive substrates to maximize heat transfer efficiency

- Uniform Heat Distribution: Strategic layer stackup design ensures even temperature distribution across the entire board surface

- Component Protection: Reduces thermal stress on critical components, extending lifespan and improving reliability

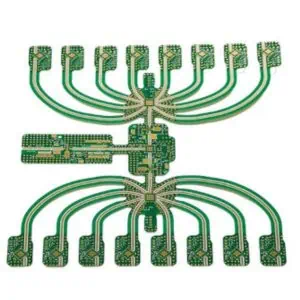

- Compact Integration: Seamlessly integrates into existing PCB designs without requiring additional cooling hardware

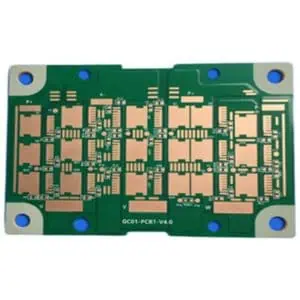

- Multi-Layer Construction: Available in various layer configurations to meet specific thermal requirements

Technical Specifications:

- Thermal conductivity: Up to 3.0 W/mK depending on substrate material

- Operating temperature range: -40°C to +150°C

- Copper thickness options: 1oz to 4oz per layer

- Compatible with standard PCB manufacturing processes

- RoHS compliant materials

Applications: Ideal for high-power LED arrays, power electronics, automotive ECUs, telecommunications equipment, server components, and any application where thermal management is critical for performance and reliability.

Benefits: Reduces the need for external heat sinks, lowers overall system costs, improves component reliability, enables higher power density designs, and simplifies thermal management in space-constrained applications.

This thermal distribution technology represents a cost-effective solution for managing heat in modern electronic systems while maintaining design flexibility and manufacturing efficiency.