Premium Electroless Nickel Immersion Gold (ENIG) PCB Manufacturing for Superior Performance and Reliability

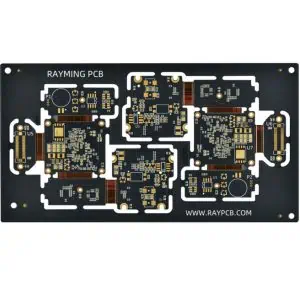

Our ENIG surface finish represents the gold standard in printed circuit board manufacturing, delivering exceptional performance for high-reliability applications. This advanced electroless plating process combines a nickel barrier layer with a thin immersion gold topcoat, creating an optimal surface for component attachment and signal integrity.

Key Features

Dual-Layer Protection System The ENIG process deposits a uniform nickel layer (typically 3-6 μm) followed by a thin gold layer (0.05-0.23 μm), providing excellent corrosion resistance and oxidation protection. This combination ensures long-term reliability even in harsh environmental conditions.

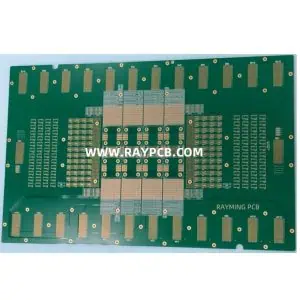

Superior Solderability The immersion gold surface maintains excellent solderability over extended periods without requiring additional preservatives. Components achieve strong, reliable solder joints with consistent wetting characteristics across the entire board surface.

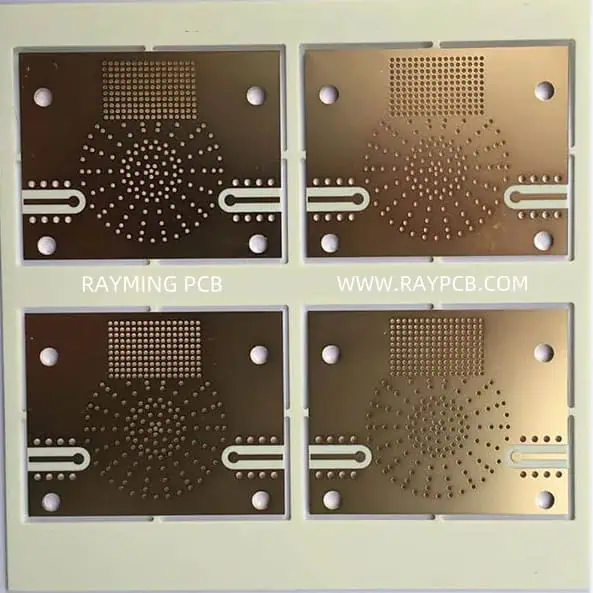

Fine Pitch Compatibility ENIG’s flat, uniform surface profile makes it ideal for fine-pitch components, BGAs, and flip-chip applications. The smooth finish eliminates issues with coplanarity that can affect component placement and soldering quality.

RoHS Compliant Our ENIG process meets all RoHS requirements, using lead-free chemistry while maintaining superior performance characteristics. This ensures compliance with international environmental regulations.

Technical Specifications

- Nickel Thickness: 3-6 micrometers

- Gold Thickness: 0.05-0.23 micrometers (2-9 microinches)

- Surface Roughness: Ra < 0.5 μm

- Shelf Life: 12+ months with proper storage

- Operating Temperature: -55°C to +125°C

Applications

ENIG surface finish excels in demanding applications including telecommunications equipment, medical devices, automotive electronics, aerospace systems, and high-frequency RF circuits. Its excellent electrical properties and corrosion resistance make it the preferred choice for mission-critical electronics.

Quality Assurance

Every ENIG-finished PCB undergoes rigorous quality control including thickness measurement, adhesion testing, and solderability verification. Our ISO 9001 certified manufacturing process ensures consistent quality and reliability across all production runs.

Contact us today to discuss your ENIG PCB requirements and experience the difference that premium gold plating makes in your electronic assemblies.