Advanced Flexible Circuit Solutions for Modern Electronics

Our Flexible Printed Circuits (FPC) represent the cutting edge of electronic interconnect technology, delivering unparalleled flexibility and reliability for today’s most demanding applications. Engineered with precision manufacturing processes and premium materials, our FPCs enable electronic designs that were once impossible with traditional rigid circuit boards.

Product Overview

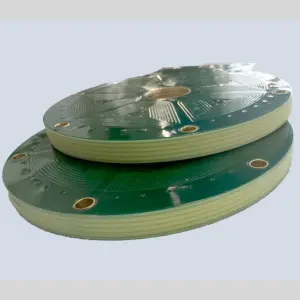

Flexible Printed Circuits are thin, lightweight electronic substrates that can bend, twist, and flex while maintaining electrical connectivity. Unlike rigid PCBs, FPCs utilize flexible polymer films as the base material, allowing for three-dimensional circuit routing and dynamic flexing applications. Our manufacturing capabilities support single-layer to complex multi-layer constructions with advanced features including rigid-flex combinations, fine-pitch components, and specialized surface finishes.

Key Features

Superior Flexibility & Durability: Our FPCs withstand millions of flex cycles while maintaining signal integrity, making them ideal for moving parts and space-constrained applications. Advanced material selection and optimized copper trace design ensure long-term reliability under continuous flexing conditions.

Space & Weight Optimization: FPCs eliminate the need for connectors and cables in many applications, reducing overall system weight by up to 70% while maximizing space utilization. The thin profile allows for compact product designs previously unachievable with traditional wiring methods.

Enhanced Signal Performance: Low dielectric loss materials and controlled impedance design deliver superior high-frequency performance with minimal signal degradation. Our manufacturing process ensures consistent electrical characteristics across the entire circuit.

Design Freedom: Three-dimensional routing capabilities enable innovative product architectures, allowing circuits to wrap around components, fit into irregular spaces, and create folding mechanisms that enhance user experience.

Manufacturing Capabilities

Our state-of-the-art production facilities feature advanced photolithographic processes, precision etching systems, and automated assembly equipment. We support trace widths down to 50 microns, via sizes as small as 75 microns, and layer counts up to 12 layers. Quality control includes automated optical inspection, electrical testing, and flex cycle validation to ensure every product meets stringent performance standards.

Applications

FPCs are essential components in smartphones, tablets, laptops, automotive electronics, medical devices, aerospace systems, and wearable technology. Common applications include display connections, camera modules, battery connectors, sensor assemblies, and mechanical actuators where traditional rigid circuits cannot perform.

Transform your next electronic design with our flexible circuit solutions – where innovation meets reliability.