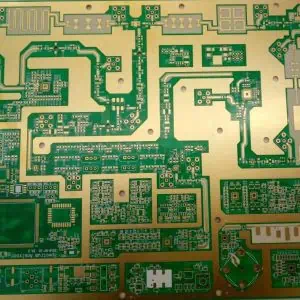

Electroless Nickel Immersion Gold (ENIG) surface finish is a popular choice for 4-layer Ball Grid Array (BGA) Printed Circuit Boards (PCBs). This finish provides excellent solderability, uniform surface planarity, and extended shelf life, making it ideal for BGA applications.

In a 4-layer BGA PCB, ENIG offers several advantages:

- Flatness: ENIG provides a consistently flat surface, crucial for proper BGA solder ball attachment.

- Fine pitch compatibility: Suitable for fine-pitch BGAs due to its thin, uniform coating.

- Corrosion resistance: The gold layer protects against oxidation and corrosion.

- Extended shelf life: ENIG-finished PCBs can be stored for longer periods without degradation.

- Multiple reflow cycles: Withstands multiple heating cycles during assembly.

The ENIG process involves depositing a thin layer of nickel (3-6 µm) followed by a thinner layer of gold (0.05-0.1 µm). This combination ensures good solderability while preventing excessive gold embrittlement in solder joints.

For 4-layer BGA PCBs, ENIG’s planarity and reliability make it an excellent choice, especially for high-density, fine-pitch applications in industries like aerospace, telecommunications, and high-performance computing.