Product Overview

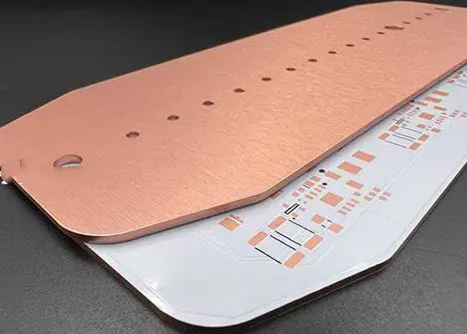

Copper Clad Laminates (CCL) are essential substrates for printed circuit board (PCB) manufacturing, consisting of high-quality dielectric materials bonded with copper foil. These precision-engineered materials form the foundation for electronic circuits across industries, from consumer electronics to aerospace applications.

Key Features

Superior Electrical Performance Our copper clad laminates deliver exceptional dielectric properties with low loss tangent and stable dielectric constant across frequency ranges. The materials maintain signal integrity while minimizing electromagnetic interference, making them ideal for high-frequency and high-speed digital applications.

Mechanical Reliability Engineered with reinforced glass fiber substrates, these laminates provide outstanding dimensional stability and mechanical strength. The materials resist warping, delamination, and thermal stress, ensuring consistent performance throughout the manufacturing process and end-use applications.

Thermal Management Advanced resin systems offer excellent thermal conductivity and heat dissipation properties. The materials maintain structural integrity across wide temperature ranges, supporting both standard and high-temperature soldering processes while preventing thermal degradation.

Technical Specifications

Substrate Options

- FR-4 standard grade for general-purpose applications

- High-Tg materials for elevated temperature requirements

- Low-loss dielectrics for RF and microwave circuits

- Flexible substrates for bendable PCB designs

- Metal-core options for enhanced thermal performance

Copper Foil Specifications

- Standard thickness: 0.5 oz to 6 oz copper weight

- High-frequency treated foil for reduced insertion loss

- Ultra-low-profile options for fine-pitch applications

- Reverse-treated foil for improved adhesion

Dimensional Accuracy

- Thickness tolerance: ±10% standard, ±5% precision grade

- Panel sizes from 12″ x 18″ to 24″ x 48″

- Custom dimensions available upon request

Applications

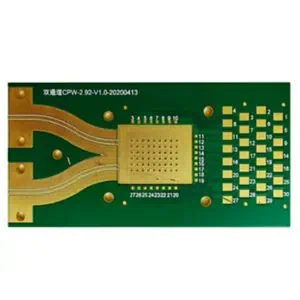

Electronics Manufacturing Ideal for multilayer PCBs, single-sided boards, and double-sided circuits in consumer electronics, telecommunications equipment, automotive systems, and industrial controls.

High-Frequency Applications Optimized for RF/microwave circuits, antenna systems, radar equipment, and wireless communication devices requiring superior signal transmission characteristics.

Specialized Industries Suitable for aerospace, medical devices, military electronics, and other applications demanding high reliability and performance standards.

Quality Assurance

All copper clad laminates undergo rigorous testing including dielectric constant measurement, peel strength evaluation, thermal stress analysis, and dimensional verification. Materials comply with IPC-4101 specifications and are manufactured in ISO 9001 certified facilities.

Environmental Compliance

Products meet RoHS and REACH regulations, supporting environmentally responsible manufacturing. Halogen-free options available for applications requiring reduced environmental impact.

Technical Support

Our engineering team provides comprehensive support including material selection guidance, design optimization recommendations, and application-specific testing services to ensure optimal performance in your PCB manufacturing processes.