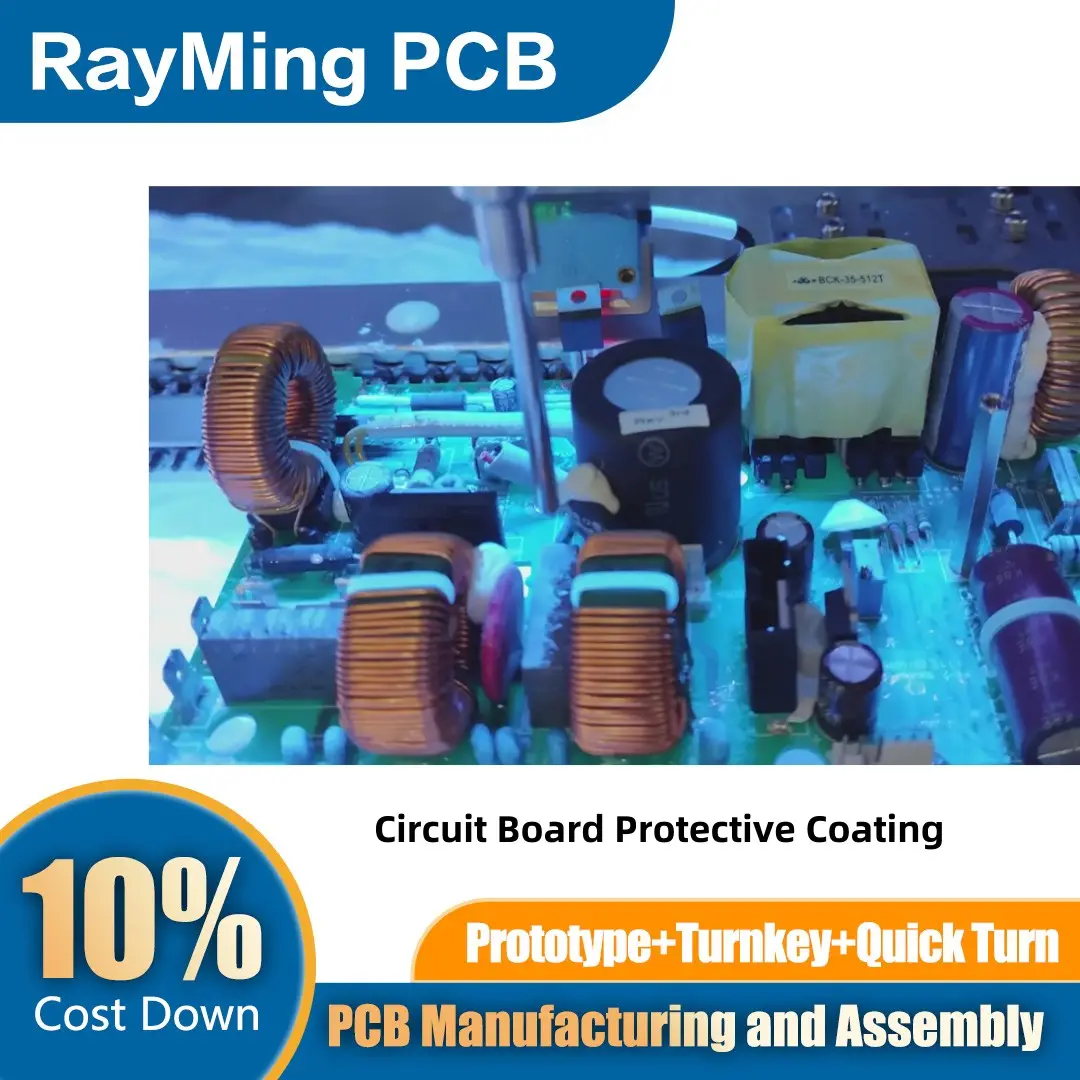

Circuit board protective coating, also known as conformal coating, is a thin polymeric film applied to printed circuit boards (PCBs) to protect them from environmental factors such as moisture, dust, chemicals, and temperature extremes. These coatings enhance the reliability and longevity of electronic components, particularly in harsh operating conditions like automotive, aerospace, industrial, and marine applications.

Common types of conformal coatings include acrylic, silicone, urethane, and epoxy, each offering unique properties such as flexibility, chemical resistance, or thermal stability. The coating is applied through methods like spraying, brushing, dipping, or selective coating, ensuring even coverage while avoiding critical areas like connectors or heat sinks.

Protective coatings also provide insulation, preventing electrical shorts caused by condensation or conductive contaminants. They are typically transparent, allowing for visual inspection of the board, and can be reworked or removed if necessary. By safeguarding PCBs from environmental stressors, conformal coatings play a vital role in ensuring the durability and performance of electronic devices.