Leading PCB Manufacturing Solutions for Electronic Innovation

Precision Circuit Board Manufacturing & Custom PCB Services

Advanced PCB manufacturing solutions designed for high-reliability electronics across automotive, aerospace, medical devices, and industrial applications. Our ISO 9001 certified facility delivers exceptional quality printed circuit boards with industry-leading turnaround times and competitive pricing.

Core PCB Manufacturing Capabilities

Custom PCB Fabrication Services

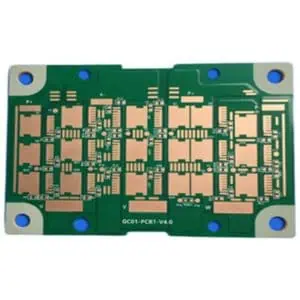

- Multilayer PCB manufacturing (2-32 layers)

- High-frequency PCB design and production

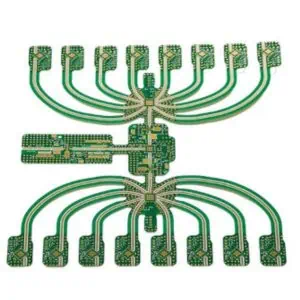

- Flexible PCB and rigid-flex PCB manufacturing

- HDI (High Density Interconnect) circuit boards

- Heavy copper PCB fabrication up to 20oz

- Aluminum PCB and metal core solutions

Advanced PCB Assembly Services

- Surface Mount Technology (SMT) assembly

- Through-hole component insertion and soldering

- Ball Grid Array (BGA) and micro-BGA assembly

- Fine-pitch component placement (0201 and smaller)

- Mixed technology PCB assembly

- Box build assembly and system integration

Quality Certifications & Standards

- ISO 9001:2015 quality management

- IPC Class 2 and Class 3 compliance

- AS9100 aerospace standard certification

- ISO 13485 medical device manufacturing

- RoHS compliant and lead-free processes

- UL recognized component program

Industry-Specific PCB Solutions

Automotive PCB Manufacturing

Specialized automotive circuit boards meeting IATF 16949 standards for:

- Engine control modules and ECUs

- Battery management systems

- Advanced driver assistance systems (ADAS)

- Electric vehicle power electronics

Medical Device PCB Assembly

FDA-compliant PCB manufacturing for critical medical applications:

- Implantable device circuits

- Diagnostic equipment PCBs

- Patient monitoring systems

- Surgical instrument electronics

Aerospace & Defense Electronics

High-reliability PCB fabrication for mission-critical applications:

- Avionics systems and flight controls

- Satellite communication boards

- Military-grade electronics

- Space-qualified PCB assemblies

Technical Manufacturing Specifications

PCB Design for Manufacturing (DFM) Optimization

- Minimum trace width: 0.075mm (3 mil)

- Via size range: 0.1mm to 0.8mm

- Layer count: Single-sided to 32-layer

- Board thickness: 0.2mm to 6.0mm

- Surface finishes: HASL, ENIG, OSP, Immersion Silver

Advanced PCB Technologies

- Embedded components and passive integration

- Via-in-pad technology for space optimization

- Blind and buried vias for complex routing

- Impedance control ±5% tolerance

- Thermal management solutions

Competitive Advantages

Fast Turnaround PCB Manufacturing

- 24-hour PCB prototyping available

- Standard lead times: 5-10 business days

- Rush PCB services: 48-72 hour delivery

- Same-day quotes for all inquiries

Cost-Effective PCB Solutions

- Volume discounts for production runs

- Design optimization to reduce manufacturing costs

- Material sourcing for component cost savings

- Lean manufacturing processes for efficiency

Global PCB Manufacturing

- North American production facility

- International shipping capabilities

- Local support and engineering assistance

- Supply chain management and logistics

Quality Assurance & Testing

Comprehensive PCB Testing

- Automated optical inspection (AOI)

- In-circuit testing (ICT)

- Functional testing and burn-in

- X-ray inspection for hidden solder joints

- Flying probe testing for prototypes

Environmental Testing

- Thermal cycling and shock testing

- Vibration and mechanical stress testing

- Salt spray corrosion resistance

- HALT/HASS accelerated life testing

Industries Served

Primary Market Sectors:

- Automotive electronics and EV systems

- Medical devices and diagnostic equipment

- Aerospace and defense applications

- Industrial automation and controls

- Telecommunications and 5G infrastructure

- Consumer electronics and IoT devices

- Energy management and renewable systems

Why Choose Our PCB Manufacturing Services?

Engineering Excellence

- 15+ years of PCB manufacturing experience

- Certified IPC trainers and quality specialists

- Design review and DFM analysis included

- Technical support throughout production

Manufacturing Capabilities

- State-of-the-art equipment and cleanroom facilities

- Scalable production from prototypes to high-volume

- Vertical integration for supply chain control

- Continuous improvement and process optimization

Customer Partnership

- Dedicated project managers for each account

- Real-time production tracking and updates

- Post-delivery support and field service

- Long-term partnership approach

Get Started with Your PCB Manufacturing Project

Ready to discuss your circuit board manufacturing needs? Our engineering team provides free DFM analysis and competitive quotes within 24 hours.

Request Your Quote:

Upload your Gerber files, BOM, and specifications for an immediate quote. Our team reviews all submissions within 2 hours during business hours.