Engineered for Extreme Environments

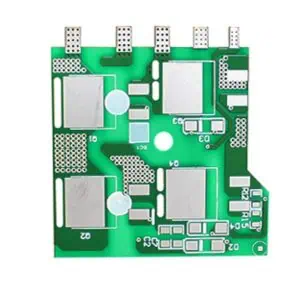

Our ceramic printed circuit boards deliver unmatched performance in demanding high-temperature applications where traditional FR-4 substrates fail. Built with advanced ceramic materials including aluminum oxide (Al₂O₃) and aluminum nitride (AlN), these PCBs maintain structural integrity and electrical performance at temperatures exceeding 300°C.

Key Features

Superior Thermal Management

- Exceptional thermal conductivity (up to 260 W/mK with AlN substrates)

- Efficient heat dissipation prevents component degradation

- Minimal thermal expansion matching semiconductor die characteristics

High Temperature Stability

- Operating temperature range: -55°C to +850°C

- Zero performance degradation at extreme temperatures

- Maintains dimensional stability under thermal cycling

Electrical Excellence

- Low dielectric loss for high-frequency applications

- Excellent electrical insulation properties

- Stable impedance characteristics across temperature ranges

- Superior signal integrity in RF/microwave applications

Mechanical Durability

- High flexural strength and fracture toughness

- Resistance to thermal shock and mechanical stress

- Hermetic sealing capabilities for harsh environments

Applications

Automotive Electronics Engine control units, exhaust sensors, and under-hood applications requiring operation at 150-200°C

Aerospace & Defense Satellite electronics, jet engine monitoring systems, and military radar applications

Industrial Processing High-temperature sensors, furnace controls, and process monitoring equipment

Power Electronics LED drivers, power modules, and high-power RF amplifiers requiring excellent heat dissipation

Oil & Gas Downhole electronics, wellhead monitoring systems, and high-temperature logging tools

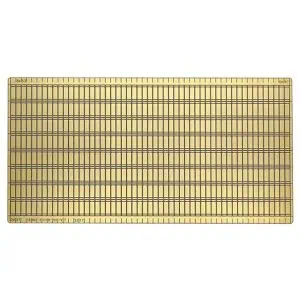

Manufacturing Capabilities

We offer comprehensive ceramic PCB solutions including single and multi-layer configurations, thick and thin film metallization, and precision via drilling. Our advanced manufacturing processes ensure consistent quality and reliability for mission-critical applications where failure is not an option.

Contact our engineering team to discuss your specific high-temperature PCB requirements and explore how our ceramic solutions can enhance your product’s performance and reliability.