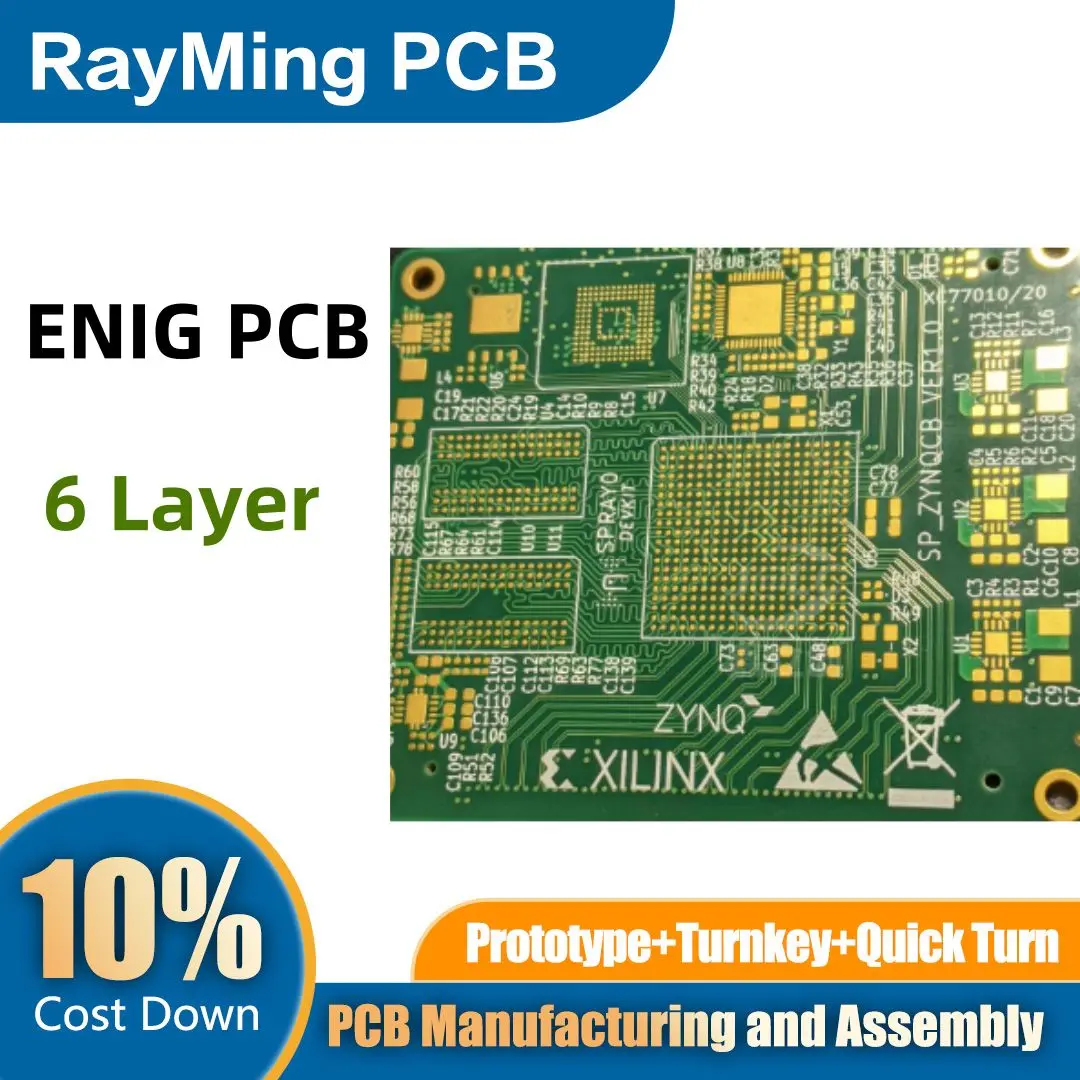

Six-layer Electroless Nickel Immersion Gold (ENIG) PCBs represent a high-performance configuration in printed circuit board manufacturing. Key features include:

-

Layer Structure: Six alternating layers of copper and insulating material, providing enhanced design complexity and signal integrity.

-

ENIG Finish: A surface treatment consisting of an electroless nickel layer (typically 3-6 µm) covered by a thin immersion gold layer (0.05-0.1 µm).

-

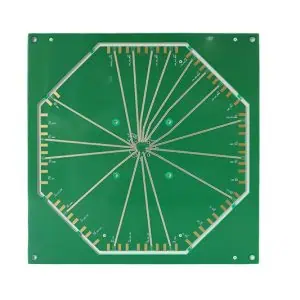

Design Flexibility: Allows for complex routing and high-density component placement across multiple layers.

-

Signal Integrity: Improved signal transmission and reduced electromagnetic interference due to the multi-layer structure.

-

Surface Characteristics:

- Excellent flatness for fine-pitch component placement

- Uniform surface finish across all layers

- Enhanced corrosion resistance and extended shelf life

-

Applications: Ideal for high-frequency circuits, telecommunications equipment, medical devices, and aerospace technology.

-

Manufacturing Process: Involves precise control of layer alignment, via formation, and ENIG plating to ensure uniform coverage and optimal performance.

-

Performance Benefits:

- Superior impedance control across all six layers

- Excellent solderability and wire bonding compatibility

- Suitable for both leaded and lead-free soldering processes

This configuration balances advanced electrical performance, reliability, and manufacturability, making it suitable for a wide range of demanding electronic applications.