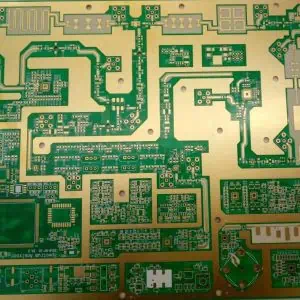

The Immersion Gold process for 4-layer PCBs is a critical final step in the ENIG (Electroless Nickel Immersion Gold) surface finish. This process involves:

-

Preparation: After electroless nickel plating, the 4-layer PCB is thoroughly cleaned and activated.

-

Immersion: The board is immersed in a gold solution containing potassium gold cyanide.

-

Ion Exchange: Gold ions in the solution displace nickel atoms on the surface through a chemical reaction, not electrolysis.

-

Controlled Deposition: The process self-limits, typically depositing 0.05-0.1 µm of gold.

-

Rinsing and Drying: The PCB is carefully rinsed and dried to remove residual chemicals.

For 4-layer PCBs, this process offers several advantages:

- Uniform gold thickness across all layers, crucial for consistent performance

- Excellent surface planarity, vital for fine-pitch components on complex boards

- Enhanced protection against nickel oxidation, ensuring long-term solderability

- Compatibility with both tin-lead and lead-free soldering processes

The Immersion Gold process provides a thin, even gold layer that protects the underlying nickel while maintaining the intricate features of 4-layer PCB designs. This finish is particularly beneficial for high-frequency applications and boards requiring extended shelf life.