PCB Components 101: Types, Functions, and Reliable Sourcing Solutions

We understand that low-cost component sourcing is fundamental to offering our customers the lowest possible cost to manufacture.By using our global purchasing teams, we are able to obtain the lowest prices in the global marketplace. Our global network of suppliers also enables us to track down components that are often hard to source.

Estimate components or full Bom Cost, Pls send bom list to Sales@raypcb.com, You will get quote very soon.

Introduction

Sourcing and procuring electronic components is a crucial part of any electronics manufacturing process. With the rapid growth of electronics manufacturing, especially for consumer electronics, automotive electronics, medical devices, and other industries, having a robust and optimized electronic component sourcing strategy is key to remaining competitive and meeting production demands. This article will provide an in-depth look at electronic component procurement, circuit board component sourcing solutions, strategies for optimizing the sourcing process, and how to build resilience into the electronics component supply chain.

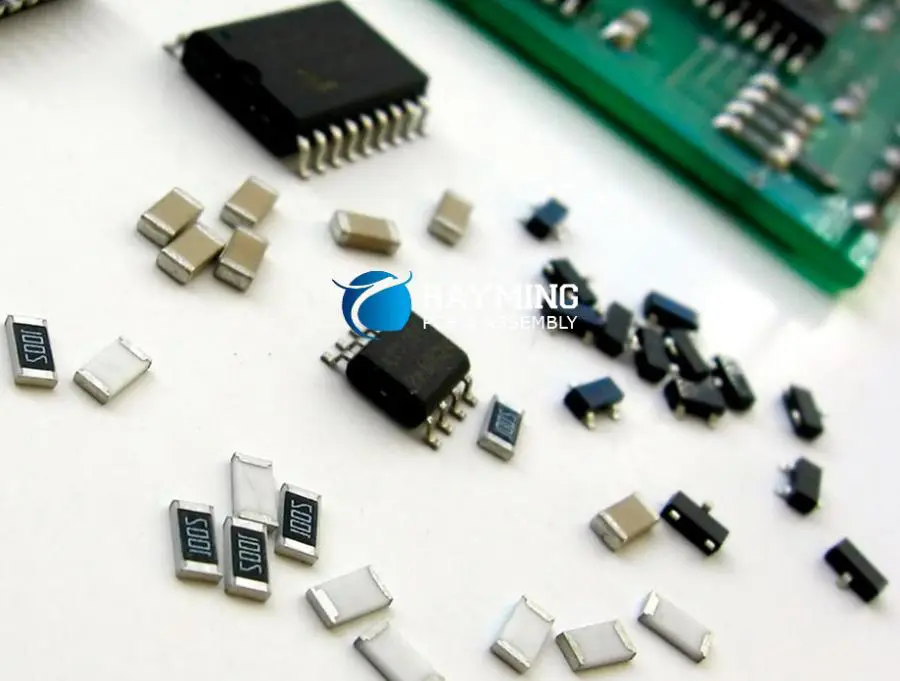

What are Electronic Circuit Board Components?

Electronic circuit board components are the fundamental elements that make up the functional parts of a printed circuit board (PCB). These components work together to create complex electronic systems, ranging from simple household appliances to advanced aerospace technologies. Each component plays a specific role in the overall functionality of the circuit, whether it’s controlling electrical current, storing energy, or processing information.

Electronic circuit board components can be broadly categorized into two main types:

Passive components: These do not require an external power source to operate and cannot introduce net energy into the circuit. Examples include resistors, capacitors, and inductors.

Active components: These require an external power source and can control voltages and currents to create gain in a circuit. Examples include transistors, diodes, and integrated circuits.

Understanding the various types of components and their functions is essential for designing efficient and reliable electronic systems. In the following sections, we’ll explore the fundamentals of circuit boards and delve deeper into the world of electronic components.

Circuit Board Fundamentals

Before we dive into the specifics of electronic components, it’s important to understand the basics of circuit boards themselves. A printed circuit board (PCB) is a flat board made of insulating material, typically fiberglass, with conductive pathways etched onto its surface. These pathways, or traces, connect various components mounted on the board, allowing electricity to flow and creating a functional electronic circuit.

Key aspects of circuit boards include:

Substrate: The base material of the PCB, usually made of fiberglass reinforced with epoxy resin (FR-4).

Copper Layer: A thin layer of copper foil bonded to the substrate, which is etched to form the conductive pathways.

Solder Mask: A thin layer of polymer applied to the copper traces to protect them from oxidation and prevent solder bridges during assembly.

Silkscreen: A layer of text and symbols printed on the board to identify components and provide other important information.

Pads and Vias: Conductive areas where component leads are soldered (pads) and holes that connect different layers of the board (vias).

Understanding these fundamental elements is crucial for grasping how electronic components interact with the circuit board and with each other.

Circuit Board Layers

Modern PCBs often consist of multiple layers, each serving a specific purpose in the overall design. The number of layers can range from single-sided boards to complex multilayer designs with 32 or more layers. Here’s an overview of common PCB layer types:

Single-sided PCBs: These have components on one side and conductive traces on the other. They are simple and cost-effective but limited in complexity.

Double-sided PCBs: These have conductive copper layers on both sides of the board, allowing for more complex circuits and higher component density.

Multilayer PCBs: These boards have three or more conductive copper layers separated by insulating layers. They allow for even greater circuit density and are commonly used in complex electronic devices.

Power and Ground Planes: In multilayer boards, entire layers are often dedicated to power distribution and grounding, improving electrical performance and reducing electromagnetic interference.

Signal Layers: These layers contain the traces that carry signals between components.

The choice of layer structure depends on the complexity of the circuit, the required performance, and cost considerations.

Circuit Board Design Considerations

Designing an effective circuit board involves more than just placing components and connecting them with traces. Several key factors must be considered to ensure optimal performance, reliability, and manufacturability:

Component Placement: Proper placement of components is crucial for efficient routing, thermal management, and signal integrity.

Trace Width and Spacing: The width of traces and the space between them affect the current-carrying capacity and signal integrity of the board.

Impedance Control: For high-speed circuits, controlling the impedance of traces is essential to maintain signal quality.

Power Distribution: Proper power distribution is critical to ensure all components receive adequate and stable power supply.

Thermal Management: Consideration must be given to heat dissipation, especially for high-power components.

EMI/EMC: Electromagnetic interference (EMI) and electromagnetic compatibility (EMC) must be addressed to ensure the board functions correctly in its intended environment.

Design for Manufacturing (DFM): The design should consider manufacturing processes to ensure the board can be produced efficiently and reliably.

Design for Testing (DFT): Incorporating features that facilitate testing can significantly improve quality control and reduce costs.

By carefully considering these factors, designers can create circuit boards that are not only functional but also reliable, efficient, and cost-effective to produce.

Types of Circuit Board Components

Electronic circuit board components can be broadly categorized into two main types: passive components and active components. Each type plays a crucial role in the functionality of electronic circuits.

Passive Circuit Board Components

Passive components do not require an external power source to operate and cannot introduce net energy into a circuit. They are fundamental elements in electronic design and are used to control and manipulate electrical current and voltage. Key characteristics of passive components include:

- They do not amplify or process signals

- They do not require a power supply to function

- They can store, dissipate, or release electrical energy

Common types of passive components include resistors, capacitors, and inductors. These components are essential for tasks such as current limiting, energy storage, and filtering in electronic circuits.

Active Components

Active components, in contrast to passive components, require an external power source to operate and can control voltages and currents to create gain in a circuit. They are capable of amplifying signals and performing complex functions. Key characteristics of active components include:

- They can amplify or process signals

- They require a power supply to function

- They can control the flow of electricity in a circuit

Examples of active components include transistors, diodes, and integrated circuits. These components are crucial for tasks such as signal amplification, switching, and information processing in electronic systems.

Understanding the distinction between passive and active components is essential for effective circuit design and troubleshooting. In the next section, we’ll explore 18 specific types of electronic circuit board components in detail.

Component harvesting

Remove obsolete components from old products or boards and reuse them in current production as available.

Refurbish equipment

Keep old component-population equipment operational in order to continue placing obsolete parts when needed.

Buy component intellectual property

If feasible, purchase licenses, documentation, and rights to fabricate obsolete proprietary components.

Identifying 18 Types of Components

Let’s dive into the specifics of 18 common types of electronic circuit board components, discussing their functions, characteristics, and applications.

1. Resistors

Resistors are passive components that resist the flow of electrical current. They are used to control voltage and current levels in a circuit.

- Function: Limit current flow, divide voltages, and protect sensitive components

- Types: Fixed resistors, variable resistors (potentiometers, trimmers)

- Applications: Current limiting, voltage dividers, pull-up/pull-down resistors

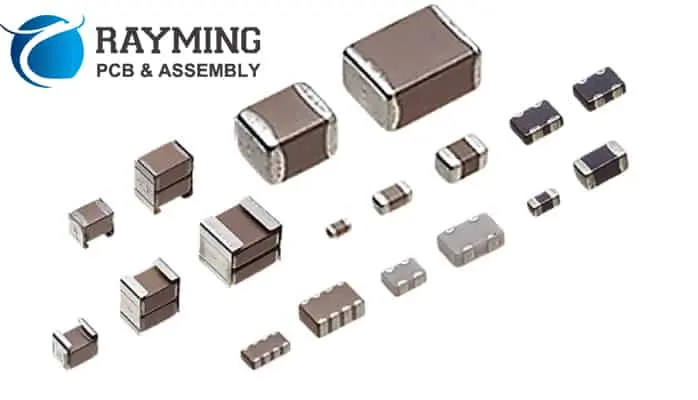

2. Capacitors

Capacitors are passive components that store electrical energy in an electric field. They can quickly charge and discharge, making them useful for various applications.

- Function: Store and release electrical energy, block DC while allowing AC to pass

- Types: Ceramic, electrolytic, film, tantalum

- Applications: Filtering, energy storage, timing circuits, coupling/decoupling

3. Inductors

Inductors are passive components that store energy in a magnetic field when current flows through them. They resist changes in current flow.

- Function: Filter signals, store energy, block high-frequency signals

- Types: Air core, iron core, ferrite core

- Applications: Filters, chokes, transformers, energy storage in switch-mode power supplies

4. Transistors

Transistors are active components that can amplify or switch electronic signals. They are fundamental building blocks of modern electronics.

- Function: Amplify signals, act as switches, regulate current

- Types: Bipolar Junction Transistors (BJTs), Field-Effect Transistors (FETs)

- Applications: Amplifiers, switches, voltage regulators, logic gates

5. Diodes

Diodes are semiconductor devices that allow current to flow in one direction while blocking it in the opposite direction.

- Function: Rectify AC to DC, protect circuits from reverse polarity

- Types: Rectifier diodes, Zener diodes, Light Emitting Diodes (LEDs)

- Applications: Rectification, voltage regulation, signal demodulation

6. Integrated Circuits (ICs)

Integrated circuits are complex electronic circuits miniaturized and packaged into a single chip. They can contain thousands or millions of transistors and other components.

- Function: Perform complex operations, process signals, store and manipulate data

- Types: Microprocessors, operational amplifiers, memory chips, logic gates

- Applications: Computing, signal processing, control systems, data storage

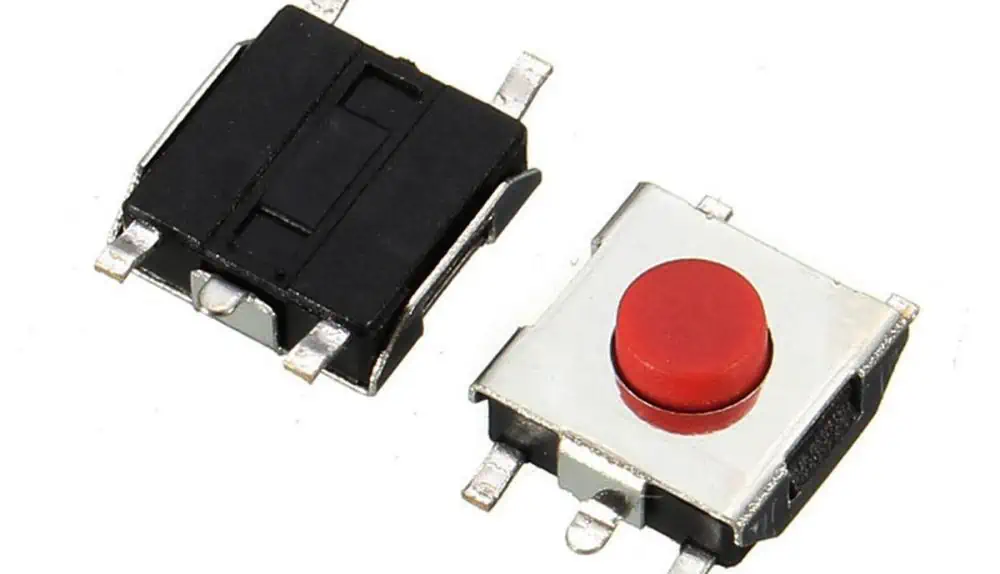

7. Switches

Switches are components used to open or close an electrical circuit, controlling the flow of current.

- Function: Control current flow, select between different circuit paths

- Types: Toggle switches, pushbutton switches, DIP switches

- Applications: Power on/off, mode selection, circuit configuration

8. Relays

Relays are electrically operated switches that use an electromagnet to mechanically operate a switch.

- Function: Control high-power circuits with low-power signals

- Types: Electromechanical relays, solid-state relays

- Applications: Industrial control systems, automotive systems, power management

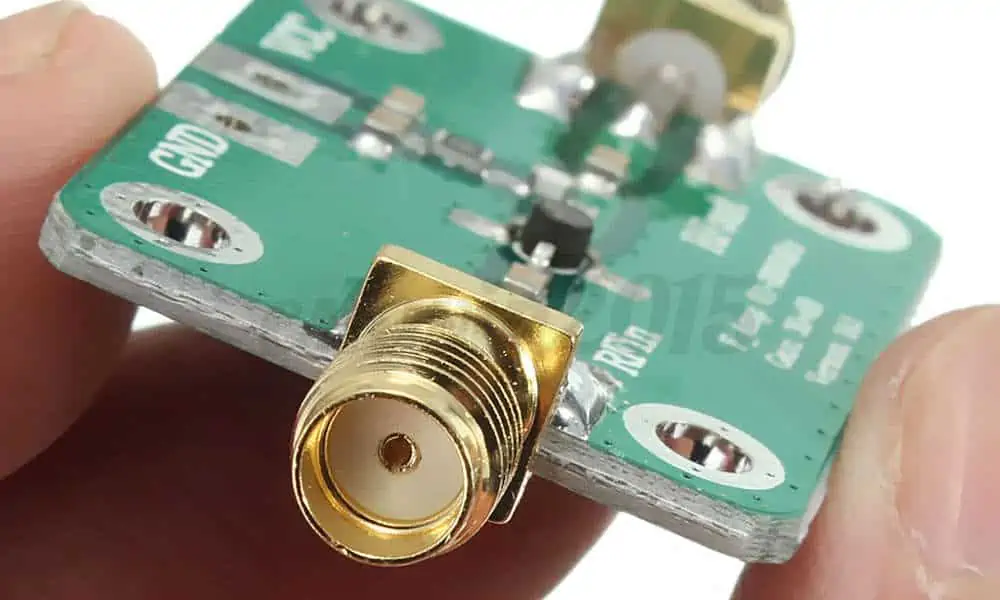

9. Connectors

Connectors provide a way to join electrical circuits together, allowing for modular design and easy maintenance.

- Function: Connect different parts of a circuit or different circuit boards

- Types: Pin headers, USB connectors, D-sub connectors, terminal blocks

- Applications: Board-to-board connections, external device interfaces, power connections

10. Crystals

Crystals are used to generate precise frequencies for timing and synchronization in electronic circuits.

- Function: Provide a stable frequency reference

- Types: Quartz crystals, ceramic resonators

- Applications: Clock generation for microcontrollers, frequency synthesis, timekeeping

11. Fuses

Fuses are safety devices that protect circuits from overcurrent conditions by melting and breaking the circuit when too much current flows.

- Function: Protect circuits and components from excessive current

- Types: Glass tube fuses, surface mount fuses, resettable fuses (PTC)

- Applications: Overcurrent protection in power supplies, battery protection, appliance safety

12. Light-Emitting Diodes (LEDs)

LEDs are semiconductor devices that emit light when an electric current passes through them.

- Function: Produce light, indicate status

- Types: Single-color LEDs, RGB LEDs, infrared LEDs

- Applications: Indicators, displays, lighting, optical communication

13. Sensors

Sensors are devices that detect and measure physical quantities and convert them into electrical signals.

- Function: Convert physical phenomena into electrical signals

- Types: Temperature sensors, pressure sensors, light sensors, accelerometers

- Applications: Environmental monitoring, process control, IoT devices

14. Microcontrollers

Microcontrollers are small computers on a single integrated circuit, containing a processor, memory, and programmable input/output peripherals.

- Function: Control and process data in embedded systems

- Types: 8-bit, 16-bit, and 32-bit microcontrollers

- Applications: Consumer electronics, automotive systems, industrial control

15. Voltage Regulators

Voltage regulators maintain a constant voltage level, protecting sensitive components from voltage fluctuations.

- Function: Maintain a stable output voltage regardless of input variations

- Types: Linear regulators, switching regulators

- Applications: Power supplies, battery-powered devices, sensitive analog circuits

16. Operational Amplifiers

Operational amplifiers (op-amps) are high-gain electronic voltage amplifiers with differential inputs and a single output.

- Function: Amplify, buffer, and perform mathematical operations on signals

- Types: General-purpose op-amps, precision op-amps, high-speed op-amps

- Applications: Signal conditioning, analog computing, active filters

17. Potentiometers

Potentiometers are variable resistors that allow for manual adjustment of resistance in a circuit.

- Function: Provide adjustable resistance for voltage division or current control

- Types: Rotary potentiometers, slide potentiometers, trimpots

- Applications: Volume control, sensor calibration, adjustable voltage dividers

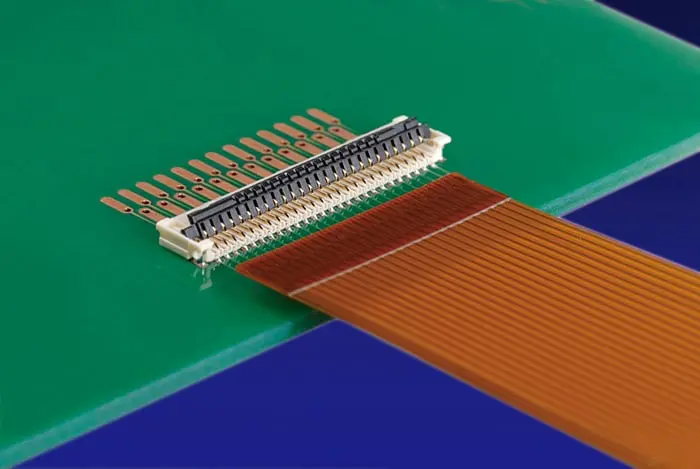

18. Cables

While not strictly components mounted on the PCB, cables are crucial for connecting circuit boards to other parts of a system or to external devices.

- Function: Transmit electrical signals or power between different parts of a system

- Types: Ribbon cables, coaxial cables, fiber optic cables

- Applications: Board-to-board connections, external device interfaces, power distribution

Understanding these components and their functions is crucial for anyone working with electronic circuit boards. In the next section, we’ll discuss factors to consider when choosing components for your circuit board design.

Factors to Consider When Choosing Circuit Board Components

Selecting the right components for your circuit board design is crucial for ensuring optimal performance, reliability, and cost-effectiveness. Here are some key factors to consider:

Electrical Specifications: Ensure the component’s voltage, current, and power ratings match your circuit requirements.

Tolerance and Accuracy: Choose components with appropriate tolerances for your application’s precision needs.

Size and Footprint: Consider the physical dimensions of components and their impact on board layout and overall device size.

Temperature Range: Ensure components can operate reliably within the expected temperature range of your device.

Reliability and Lifespan: Consider the expected lifespan of components, especially for products intended for long-term use.

Cost: Balance performance requirements with budget constraints, considering both unit cost and total cost of ownership.

Availability: Choose components that are readily available to avoid supply chain issues and production delays.

Environmental Considerations: Consider factors such as humidity, vibration, and electromagnetic interference in the operating environment.

Regulatory Compliance: Ensure components meet relevant industry standards and regulations (e.g., RoHS, REACH).

Manufacturability: Consider how easily components can be assembled and soldered onto the PCB.

By carefully considering these factors, you can select components that will contribute to a successful and reliable circuit board design.

Circuit Board Component Reference Designators

Reference designators are standardized codes used to identify and label components on a circuit board. They provide a common language for designers, manufacturers, and technicians to communicate about specific components. Here are some common reference designator prefixes:

- R: Resistor

- C: Capacitor

- L: Inductor

- D: Diode

- Q: Transistor

- U: Integrated Circuit

- SW: Switch

- J: Connector

- Y: Crystal or Oscillator

- F: Fuse

- T: Transformer

For example, “R1” might refer to the first resistor in the circuit, while “C12” could indicate the twelfth capacitor. Using standardized reference designators helps streamline the design, assembly, and troubleshooting processes.

Effective Electronic Component Sourcing Tips

Sourcing high-quality, reliable components is crucial for the success of your electronic projects. Here are some tips for effective component sourcing:

Use Reputable Suppliers: Work with well-established, authorized distributors to ensure component authenticity and quality.

Consider Lead Times: Plan ahead and consider component availability and lead times to avoid production delays.

Evaluate Multiple Sources: Don’t rely on a single supplier; diversify your sources to mitigate supply chain risks.

Check for Certifications: Ensure suppliers have relevant quality certifications (e.g., ISO 9001) and comply with industry standards.

Beware of Counterfeits: Implement strict quality control measures to detect and prevent counterfeit components.

Leverage Technology: Use online marketplaces and inventory management systems to streamline your sourcing process.

Build Relationships: Develop strong relationships with key suppliers to negotiate better terms and secure priority during shortages.

Consider Alternate Parts: Identify and qualify alternative components to provide flexibility in your designs and sourcing strategy.

Stay Informed: Keep up-to-date with industry trends, component obsolescence, and emerging technologies.

Implement a Quality Management System: Establish clear procedures for component selection, inspection, and testing.

By following these tips, you can improve the reliability of your component sourcing process and reduce the risk of supply chain disruptions.

One-Stop Circuit Board Manufacturing and Electronic Components Sourcing Solution

In today’s fast-paced electronics industry, time-to-market is crucial. Many companies are turning to one-stop solutions that offer both PCB manufacturing and component sourcing services. These integrated solutions provide numerous benefits:

Streamlined Process: By combining PCB manufacturing and component sourcing, you can simplify your supply chain and reduce coordination efforts.

Reduced Lead Times: One-stop solutions can often offer faster turnaround times by optimizing the entire production process.

Improved Quality Control: With a single provider handling both PCB production and component sourcing, there’s better oversight and consistency in quality control measures.

Cost Efficiency: Bundling services can often lead to cost savings through economies of scale and reduced logistics expenses.

Enhanced Communication: Working with a single provider simplifies communication and reduces the risk of miscommunication between multiple parties.

Expertise Across the Board: One-stop solution providers typically have expertise in both PCB manufacturing and component sourcing, offering valuable insights throughout the process.

Flexibility and Customization: These providers can often offer more flexible and customized solutions to meet specific project requirements.

Simplified Troubleshooting: If issues arise, having a single point of contact for both PCB and components can simplify the troubleshooting process.

When choosing a one-stop solution provider, consider the following factors:

Range of Services: Ensure they offer all the services you need, from PCB design and manufacturing to component sourcing and assembly.

Quality Certifications: Look for providers with relevant industry certifications (e.g., ISO 9001, IPC standards).

Technical Capabilities: Verify that they can handle the complexity and volume of your projects.

Component Sourcing Network: Assess their network of suppliers and their ability to source both common and specialized components.

Turnaround Time: Compare their lead times with your project requirements.

Customer Support: Evaluate their customer service and technical support capabilities.

Pricing Structure: Understand their pricing model and how it compares to using separate providers for PCB manufacturing and component sourcing.

By leveraging a one-stop solution, you can streamline your electronic product development process, potentially reducing time-to-market and overall costs while maintaining high quality standards.

The Future of Electronic Circuit Board Components

As technology continues to evolve at a rapid pace, the world of electronic circuit board components is also undergoing significant changes. Here are some trends and developments to watch:

Miniaturization: Components are becoming smaller and more densely packed, allowing for more powerful and compact devices.

Increased Integration: More functions are being integrated into single chips, reducing the number of discrete components needed.

Advanced Materials: New materials are being developed for both PCBs and components, offering improved performance and durability.

Flexible and Stretchable Electronics: The development of flexible and stretchable components is enabling new form factors and applications.

Internet of Things (IoT): The growth of IoT is driving demand for low-power, wireless-enabled components.

Artificial Intelligence (AI) and Machine Learning: Specialized AI chips and components are becoming more prevalent in various applications.

Sustainability: There’s a growing focus on developing more environmentally friendly components and manufacturing processes.

3D Printing: Advancements in 3D printing technology are opening up new possibilities for custom component and PCB manufacturing.

Quantum Computing: While still in its early stages, quantum computing may lead to entirely new types of electronic components.

Enhanced Thermal Management: As devices become more powerful and compact, advanced thermal management solutions are being integrated into components and PCBs.

Staying informed about these trends can help designers and engineers prepare for the future of electronic circuit board design and manufacturing.

Conclusion

Electronic circuit board components are the building blocks of modern technology, enabling the creation of devices that power our digital world. From passive components like resistors and capacitors to active components like transistors and integrated circuits, each element plays a crucial role in the functionality of electronic systems.

Understanding the various types of components, their functions, and the factors to consider when selecting them is essential for anyone involved in electronic design and manufacturing. Moreover, effective sourcing strategies and leveraging one-stop solutions can significantly streamline the production process and improve overall efficiency.

As technology continues to advance, the landscape of electronic components will evolve, presenting both challenges and opportunities. By staying informed about current trends and future developments, professionals in the electronics industry can position themselves to create innovative, efficient, and reliable products that meet the demands of tomorrow’s technology-driven world.

Whether you’re a seasoned engineer or just starting your journey in electronics, continuous learning and adaptation are key to success in this dynamic field. Embrace the complexity, stay curious, and remember that every great electronic device starts with the thoughtful selection and arrangement of these fundamental components on a circuit board.