In the world of electronics manufacturing, printed circuit boards (PCBs) are the backbone of countless devices. As these devices become more complex and are used in increasingly diverse environments, protecting PCB assemblies from external factors becomes crucial. One of the most effective methods of protection is conformal coating. This article explores the concept of conformal coating, its benefits, applications, and helps you determine whether your PCB assembly needs this protective measure.

What is Conformal Coating?

Definition and Purpose

Conformal coating is a thin protective chemical coating applied to PCB assemblies to protect the electronic components from environmental stresses. The coating “conforms” to the contours of the PCB, providing a uniform protective layer.

Types of Conformal Coatings

There are several types of conformal coatings, each with its own characteristics and applications:

| Coating Type | Key Features | Best For |

| Acrylic (AR) | Easy to apply and remove, good moisture resistance | General purpose, prototyping |

| Urethane (UR) | Excellent chemical and abrasion resistance | Harsh chemical environments |

| Silicone (SR) | High temperature resistance, very flexible | Extreme temperatures, high humidity |

| Epoxy (ER) | Strong chemical and abrasion resistance | Demanding environments, long-term protection |

| Parylene | Thin, uniform coating, excellent barrier properties | Medical devices, aerospace applications |

Application Methods

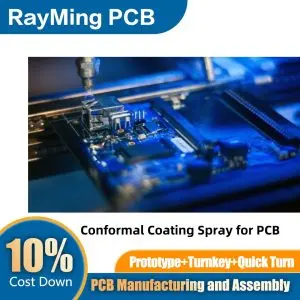

Conformal coatings can be applied using various techniques:

- Dipping

- Spraying

- Brushing

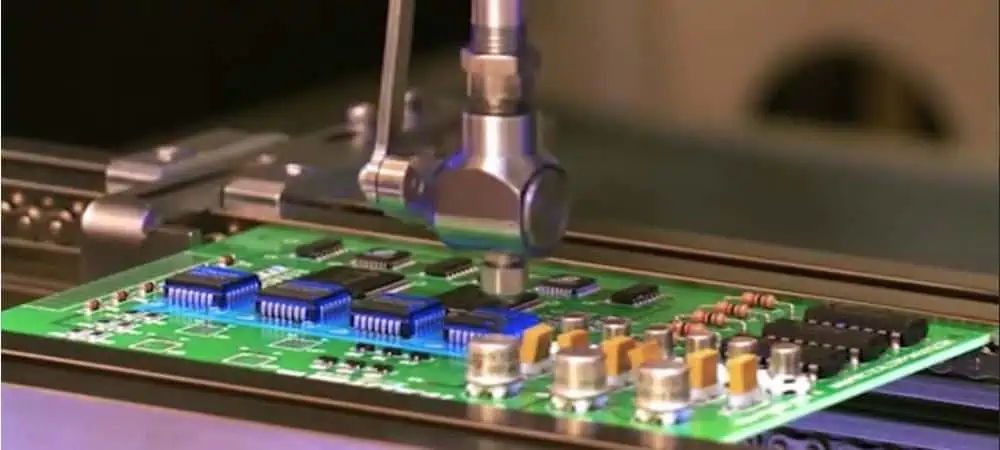

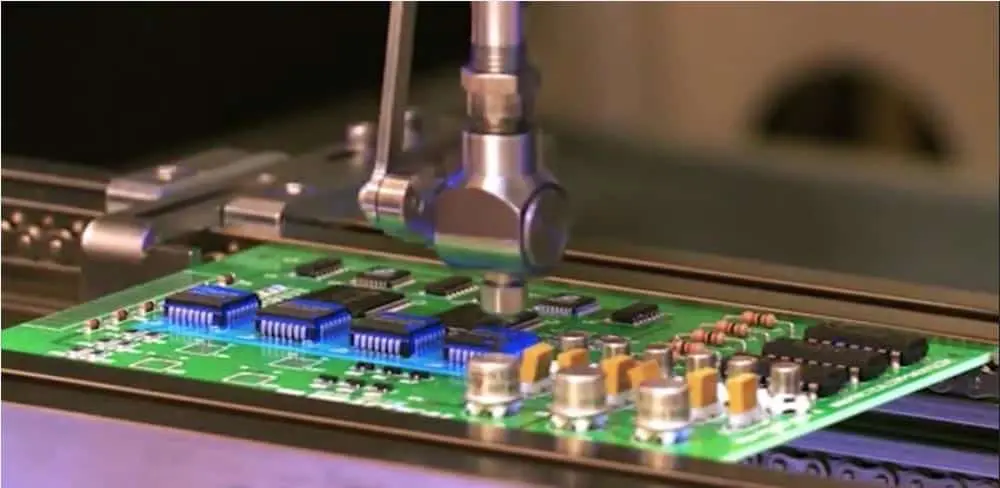

- Selective coating

- Vapor deposition (for Parylene)

Each method has its advantages and is chosen based on the PCB design, production volume, and required precision.

Benefits of Conformal Coating

Environmental Protection

Moisture Resistance

Conformal coatings create a barrier against moisture, preventing corrosion and electrical shorts.

Temperature Resistance

Certain coatings can protect PCBs from extreme temperatures, both hot and cold.

Chemical Protection

Coatings shield components from exposure to harmful chemicals and solvents.

Mechanical Protection

Vibration and Shock Resistance

Coatings can absorb some of the stress from vibrations and shocks, protecting delicate components.

Abrasion Protection

The coating layer guards against physical wear and tear.

Electrical Benefits

Improved Dielectric Strength

Coatings increase the insulation between components, reducing the risk of arcing and short circuits.

Prevention of Dendrite Growth

Coatings inhibit the growth of conductive dendrites that can cause short circuits over time.

Extended Lifespan

By protecting against various environmental and physical stresses, conformal coatings can significantly extend the life of PCB assemblies.

When to Consider Conformal Coating

Environmental Factors

Consider conformal coating if your PCB will be exposed to:

- High humidity or moisture

- Salt spray or corrosive atmospheres

- Extreme temperatures

- Chemicals or solvents

Application-Specific Requirements

Certain industries and applications often require conformal coating:

| Industry | Common Requirements |

| Automotive | Temperature extremes, vibration, chemicals |

| Aerospace | Altitude changes, temperature fluctuations |

| Marine | High humidity, salt spray |

| Industrial | Chemicals, dust, vibration |

| Medical | Biocompatibility, sterilization resistance |

Regulatory Compliance

Some industries have regulations that mandate the use of conformal coatings for safety and reliability.

Factors to Consider Before Applying Conformal Coating

PCB Design Considerations

Component Selection

Some components may not be suitable for coating or may require masking.

Layout and Spacing

Adequate spacing between components is necessary for proper coating coverage.

Test Points and Connectors

Areas that require electrical contact may need to be masked before coating.

Cost Analysis

While conformal coating adds to the production cost, it should be weighed against:

- Potential warranty claims

- Product failures in the field

- Brand reputation damage

Production Process Impact

Implementing conformal coating may require:

- Additional equipment

- Extended production time

- Quality control measures

Repairability

Coated PCBs can be more challenging to repair, which should be considered for products that may require field servicing.

The Conformal Coating Process

Pre-Coating Preparation

- Cleaning the PCB assembly

- Masking areas that should not be coated

- Pre-heating (if required)

Coating Application

The chosen application method is used to apply the coating evenly across the PCB.

Curing

Depending on the coating type, curing may involve:

- Heat curing

- UV curing

- Moisture curing

- Room temperature curing

Quality Control

Post-coating inspection may include:

- Visual inspection

- Thickness measurement

- Continuity testing

Challenges and Considerations

Common Issues

| Issue | Cause | Solution |

| Bubbles | Trapped air, improper application | Adjust application technique, use vacuum to remove air |

| Delamination | Poor surface preparation, incompatible materials | Improve cleaning process, choose compatible coating |

| Incomplete coverage | Improper application technique | Adjust application method, multiple coats if necessary |

| Orange peel effect | Improper spraying technique | Adjust spray parameters, consider dif |

Material Compatibility

Ensure the chosen coating is compatible with:

- PCB substrate material

- Component materials

- Solder mask

- Labels and markings

Thickness Control

Maintaining the right coating thickness is crucial for:

- Adequate protection

- Avoiding excess weight

- Preventing thermal insulation issues

Masking and Keep-Out Areas

Proper masking is essential for:

- Connectors

- Test points

- Adjustable components

- Heat sinks

Alternatives to Conformal Coating

Potting and Encapsulation

For extreme environments, potting the entire PCB in a protective resin may be more suitable.

Sealed Enclosures

Using hermetically sealed enclosures can provide protection without coating the PCB directly.

Ruggedized PCB Design

Designing the PCB with built-in protection features can reduce the need for additional coating.

Future Trends in Conformal Coating

Nano-Coatings

Ultra-thin nano-coatings are being developed for better protection with minimal impact on PCB properties.

Smart Coatings

Self-healing and self-diagnosing coatings are emerging technologies that could revolutionize PCB protection.

Environmentally Friendly Options

New coating formulations are focusing on reducing environmental impact and improving sustainability.

Conclusion

Conformal coating can significantly enhance the reliability and longevity of PCB assemblies, especially in challenging environments. While it adds complexity and cost to the manufacturing process, the benefits often outweigh these factors for many applications. By carefully considering the specific needs of your PCB assembly and the environment it will operate in, you can make an informed decision about whether conformal coating is necessary for your project.

As technology continues to advance, we can expect to see new coating materials and application methods that offer even better protection with fewer drawbacks. Staying informed about these developments will help ensure that your PCB assemblies remain protected and reliable in an ever-evolving technological landscape.

Frequently Asked Questions (FAQ)

1. How long does conformal coating typically last?

The lifespan of conformal coating depends on the type of coating used and the environmental conditions. Generally, a well-applied conformal coating can last anywhere from 5 to 10 years or even longer in controlled environments. However, in harsh conditions or with constant exposure to extreme temperatures or chemicals, the coating may degrade more quickly.

2. Can conformal coating be removed if repairs are needed?

Yes, conformal coating can be removed for repairs, but the process can be challenging and time-consuming. The removal method depends on the type of coating used. Some coatings can be removed with solvents, while others may require mechanical abrasion or specialized removal techniques. It’s important to note that the removal process can potentially damage components if not done carefully.

3. Are there any components that should not be coated?

Yes, certain components should not be coated or require special consideration:

- Connectors and sockets

- Switches and relays

- Potentiometers and trimmers

- Some types of sensors

- Components that generate significant heat

These components may need to be masked before coating or may require selective coating techniques.

4. How thick should the conformal coating be?

The ideal thickness of conformal coating typically ranges from 25 to 250 micrometers (1 to 10 mils), depending on the specific coating type and application requirements. Thinner coatings may not provide adequate protection, while excessively thick coatings can lead to issues with heat dissipation and component stress.

5. Can conformal coating affect the electrical properties of the PCB?

While conformal coating is designed to have minimal impact on electrical properties, it can affect them in some ways. The coating may slightly change the capacitance between closely spaced conductors and can impact the performance of high-frequency circuits. Additionally, some coatings may affect the dielectric constant of the PCB. These factors should be considered during the design phase, especially for sensitive or high-frequency applications.