Revolutionize Your Electronics Design with Advanced Rigid-Flex Technology

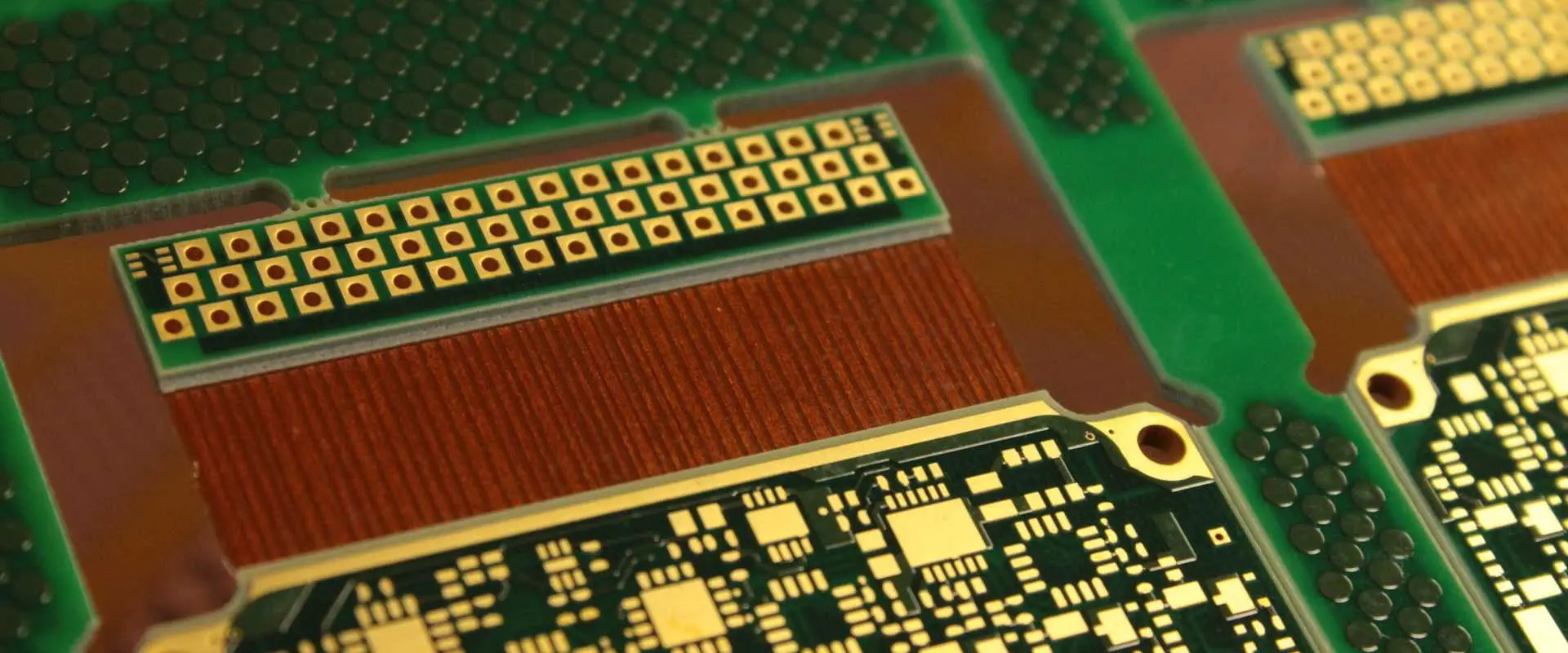

Our Rigid Flex PCB Assembly combines the structural integrity of rigid boards with the flexibility of flex circuits, delivering innovative solutions for space-constrained and dynamic applications. This hybrid technology eliminates the need for connectors and cables while providing superior reliability and performance.

Key Features

Seamless Integration: Rigid sections provide stable mounting points for components while flexible areas enable smooth transitions between different board planes, reducing assembly complexity and potential failure points.

Space Optimization: Dramatically reduces overall device footprint by eliminating bulky connectors and wire harnesses. The three-dimensional design capability allows for compact, lightweight product architectures.

Enhanced Reliability: Fewer interconnections mean reduced risk of connection failures. The monolithic construction withstands vibration, thermal cycling, and mechanical stress better than traditional rigid board-to-board connections.

Design Flexibility: Accommodates complex geometries and tight bend radii, enabling innovative product form factors. Supports both static and dynamic flexing applications with controlled impedance throughout the entire circuit path.

Technical Specifications

- Layer Count: 2-20 layers in rigid sections, 1-8 layers in flex regions

- Material Options: FR-4 rigid sections with polyimide flex circuits

- Bend Radius: Down to 1:1 ratio (thickness to bend radius)

- Operating Temperature: -55°C to +125°C

- Thickness: 0.1mm to 3.2mm (varies by section)

- Via Technology: Through-hole, blind, buried, and microvias supported

Applications

Perfect for aerospace systems, medical devices, automotive electronics, wearable technology, and high-density consumer electronics where space, weight, and reliability are critical factors.

Experience the future of PCB technology – contact us today for custom rigid-flex solutions tailored to your specific requirements.