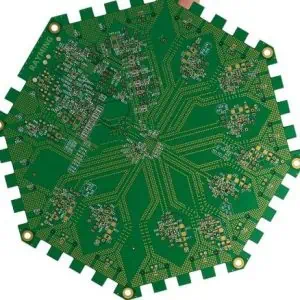

Our comprehensive In Circuit Testing (ICT) service provides thorough validation of your printed circuit board assemblies through precise electrical verification and functional analysis. This essential quality assurance process ensures your PCBAs meet exact specifications before moving to production or deployment.

Key Testing Capabilities:

Our advanced ICT systems perform detailed component-level verification, measuring resistance, capacitance, inductance, and continuity across all circuit nodes. We test both analog and digital components, verify proper component placement and orientation, and detect manufacturing defects such as solder bridges, open circuits, and component failures.

Technical Features:

The testing process utilizes high-precision test fixtures custom-designed for your specific PCB layout, enabling access to critical test points and component pads. Our equipment supports a wide range of component types including resistors, capacitors, inductors, diodes, transistors, integrated circuits, and complex programmable devices.

Quality Assurance Benefits:

ICT provides immediate feedback on assembly quality, catching defects early in the manufacturing process when correction costs are minimal. The automated testing eliminates human error, provides consistent repeatability, and generates detailed test reports with pass/fail status for each component and circuit node.

Service Specifications:

We accommodate PCB assemblies from prototype quantities to high-volume production runs. Our testing covers supply voltages from 1.2V to 300V, supports both surface mount and through-hole components, and includes boundary scan testing for complex digital devices. Typical test coverage exceeds 95% of all assembled components.

Industries Served:

Our ICT services support automotive electronics, medical devices, aerospace systems, telecommunications equipment, industrial controls, and consumer electronics manufacturing where reliability and performance are critical requirements.