Protect Your Electronics with Professional Conformal Coating

Our conformal coating services provide essential protection for your printed circuit boards (PCBs) and electronic assemblies against environmental hazards, moisture, chemicals, and mechanical stress. As a thin polymeric film applied directly to circuit boards, our conformal coatings ensure reliable performance and extended lifespan for your critical electronic components.

Comprehensive Protection Against Environmental Threats

Moisture & Humidity Defense: Our coatings create an impermeable barrier that prevents moisture ingress, eliminating risks of corrosion, short circuits, and component degradation in high-humidity environments.

Chemical Resistance: Protect your PCBs from exposure to acids, alkalis, solvents, and other corrosive substances commonly found in industrial settings, automotive applications, and outdoor installations.

Temperature Stability: Our coating solutions maintain protective integrity across extreme temperature ranges, from -65°C to +200°C, ensuring consistent performance in demanding thermal conditions.

Dust & Particle Protection: Prevent contamination from airborne particles, dust, and debris that can cause component failure or signal interference in sensitive electronic systems.

Advanced Coating Technologies

Acrylic Coatings: Fast-drying, easy-to-apply solutions ideal for general-purpose protection with excellent dielectric properties and optical clarity.

Silicone Coatings: Superior flexibility and temperature resistance, perfect for applications requiring thermal cycling resistance and long-term durability.

Polyurethane Coatings: Premium chemical and abrasion resistance with excellent adhesion properties for harsh industrial environments.

UV-Cure Coatings: Rapid processing with precise thickness control, offering exceptional uniformity and production efficiency for high-volume applications.

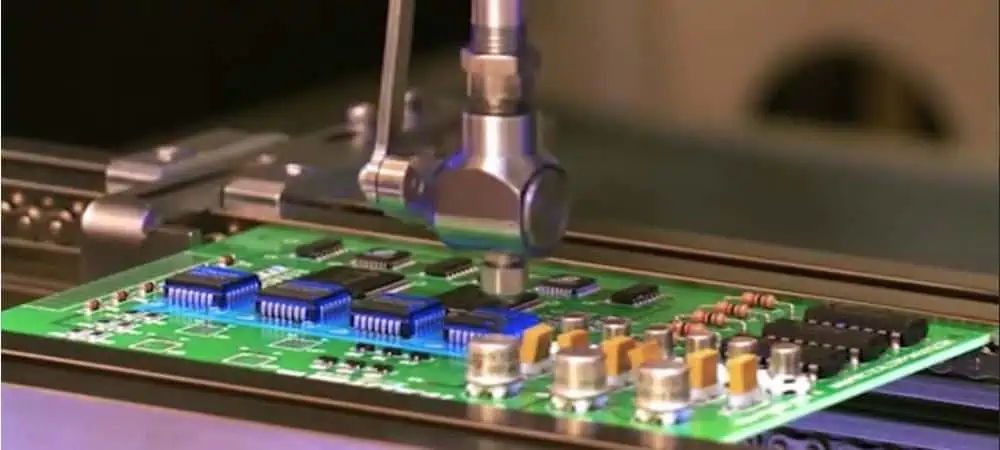

Professional Application Methods

Our certified technicians utilize multiple application techniques to ensure optimal coverage and performance:

- Spray Coating: Uniform application for complex geometries and high-volume production

- Dip Coating: Complete coverage for maximum protection in challenging environments

- Brush Application: Precision coating for selective area protection and repair work

- Selective Coating: Automated dispensing for precise component-level protection

Quality Assurance & Testing

Every coating application undergoes rigorous quality control including:

- Thickness measurement and uniformity verification

- Adhesion testing to industry standards

- Dielectric strength and insulation resistance testing

- Thermal cycling and environmental stress testing

- Visual inspection for complete coverage and defect detection

Industry Applications

Automotive Electronics: Engine control units, sensors, and infotainment systems requiring protection from temperature extremes, vibration, and chemical exposure.

Aerospace & Defense: Mission-critical avionics, communication systems, and military electronics operating in extreme environments.

Industrial Controls: PLCs, motor drives, and automation equipment exposed to harsh manufacturing environments.

Medical Devices: Life-critical equipment requiring biocompatible protection and reliable long-term performance.

Consumer Electronics: Outdoor equipment, marine electronics, and portable devices needing weather resistance.

Benefits That Drive Value

Extended Product Lifespan: Significantly reduce field failures and warranty claims by protecting against environmental damage.

Reduced Maintenance Costs: Minimize cleaning requirements and component replacement schedules.

Enhanced Reliability: Ensure consistent performance in challenging operating conditions.

Compliance Assurance: Meet industry standards including IPC-CC-830, MIL-I-46058, and UL746E requirements.

Customized Solutions: Tailored coating specifications to match your specific application requirements and performance criteria.

Technical Specifications

- Coating Thickness: 25-250 microns (application-dependent)

- Dielectric Strength: Up to 7kV/mm

- Operating Temperature: -65°C to +200°C (material-dependent)

- Humidity Resistance: 95% RH at 40°C

- Salt Spray Resistance: 1000+ hours (ASTM B117)

- Thermal Shock: -40°C to +125°C cycling capability

Get Started Today

Partner with our conformal coating experts to develop the optimal protection strategy for your electronic assemblies. Our experienced team provides comprehensive consultation, material selection guidance, and ongoing technical support to ensure your products achieve maximum reliability and performance.

Contact us for a detailed application assessment and customized coating solution that meets your specific protection requirements and budget objectives.