World-Class PCB Assembly Manufacturing from China’s Leading Electronics Hub

Leverage China’s advanced electronics manufacturing ecosystem with our comprehensive printed circuit board assembly services. We combine cutting-edge technology, skilled craftsmanship, and competitive pricing to deliver exceptional PCBA solutions for global customers across all industries.

Why Choose China for PCBA Services

China’s electronics manufacturing infrastructure offers unparalleled advantages including access to the world’s largest component supply chain, advanced production facilities, and decades of electronics assembly expertise. Our China-based operations provide cost-effective solutions without compromising on quality or reliability.

Strategic Advantages:

- Access to global component suppliers and distributors

- Advanced SMT production lines with Industry 4.0 capabilities

- Experienced engineering teams with multilingual support

- Flexible production volumes from prototypes to millions of units

- Comprehensive supply chain management

- Faster time-to-market with integrated services

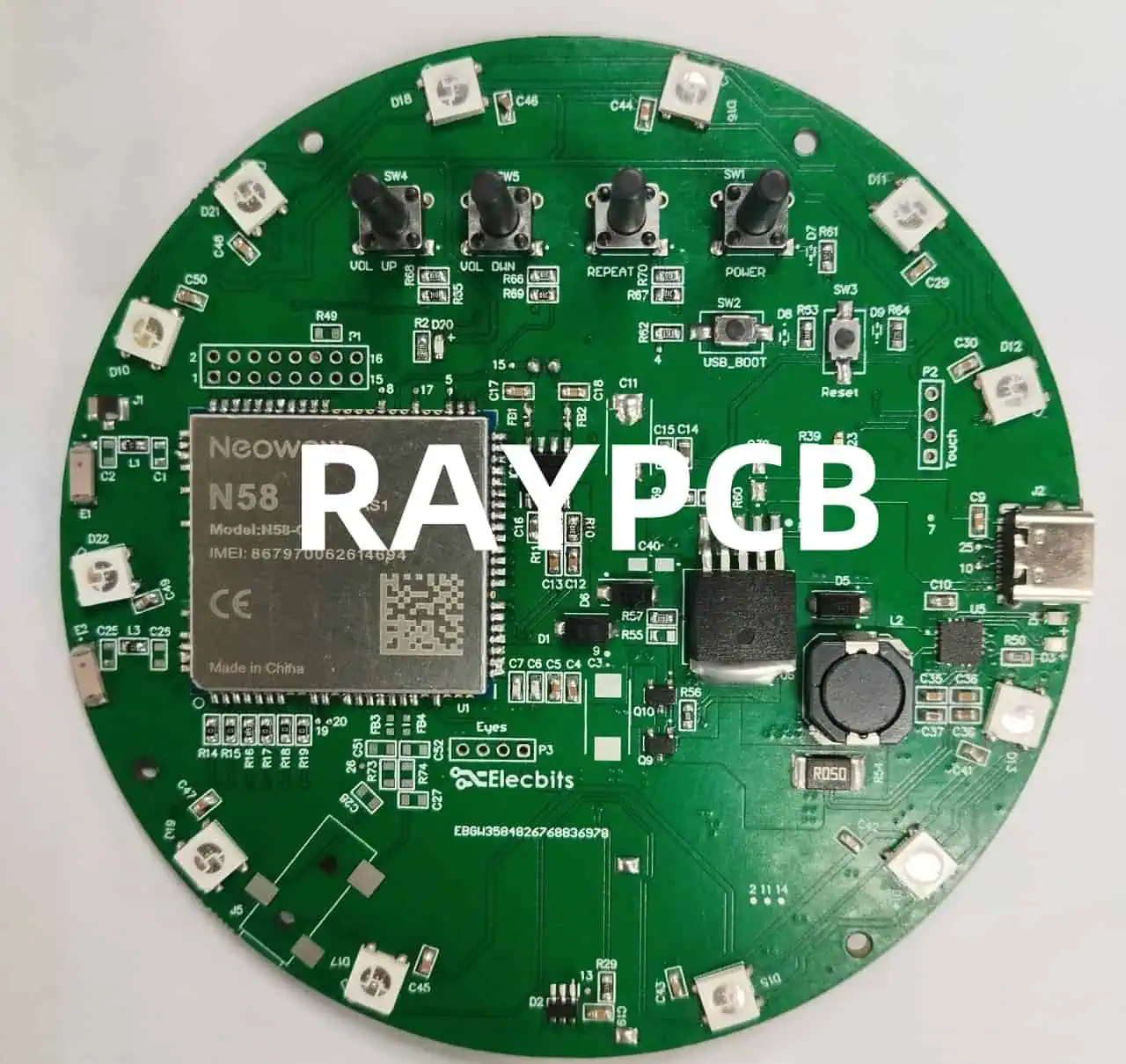

Complete PCBA Manufacturing Services

Our China facilities offer end-to-end PCB assembly services covering every aspect of electronic manufacturing. From initial design support to final product testing, we streamline the entire production process under one roof.

Core Assembly Services:

- Surface Mount Technology (SMT) assembly

- Through-hole component insertion and soldering

- Ball Grid Array (BGA) and micro-BGA assembly

- Fine-pitch component placement (down to 0201 and 01005)

- Mixed technology PCB assembly

- Multi-layer rigid and flexible PCB assembly

- High-density interconnect (HDI) assembly

- System-level box build and integration

Advanced Manufacturing Capabilities

Our state-of-the-art production facilities feature the latest assembly equipment from industry leaders including Fuji, Panasonic, and Yamaha placement machines, precision reflow ovens, and automated inspection systems.

Technical Specifications:

- Placement accuracy: ±0.02mm

- Component range: 01005 to large connectors

- BGA pitch: Down to 0.3mm

- Assembly layers: Single to 20+ layer PCBs

- Production capacity: 50M+ components per day

- Lead times: 3-15 days depending on complexity

Quality Assurance & Testing

Every assembly undergoes comprehensive quality control including automated optical inspection (AOI), in-circuit testing (ICT), functional testing, and boundary scan testing. Our ISO 9001, ISO 14001, and IATF 16949 certifications ensure consistent quality standards.

Quality Control Process:

- Incoming component inspection and verification

- Solder paste inspection (SPI)

- Real-time SMT process monitoring

- Post-reflow AOI and X-ray inspection

- Electrical and functional testing

- Final quality audit and packaging

Component Sourcing & Supply Chain

Benefit from China’s extensive component ecosystem with access to authorized distributors, original manufacturers, and specialized suppliers. We provide complete supply chain management including component procurement, inventory management, and obsolescence protection.

Industries & Applications

Our China PCBA services support diverse sectors including consumer electronics, automotive electronics, medical devices, industrial automation, telecommunications, renewable energy systems, and emerging technologies like IoT and AI hardware.

Global shipping and logistics support – delivering quality Chinese manufacturing to customers worldwide with full traceability and after-sales support.